Mar dhuine atá ag obair ar an líne réirde againn taipéalaithe teicneolaíochta, aimsíodh agam go mbíonn go leor cásanna éadachta ola nó neamhréir siabhra nár tharla mar gheall ar an siabhrán féin, ach de bharr sonraí a néiltear i rith na suiteála. Cuireann na moltais phráinneacha seo a leanas ina chuidleadh eisiachtaí coitianta agus bearta is fearr le haghaidh teicníoch agus custaiméirí.

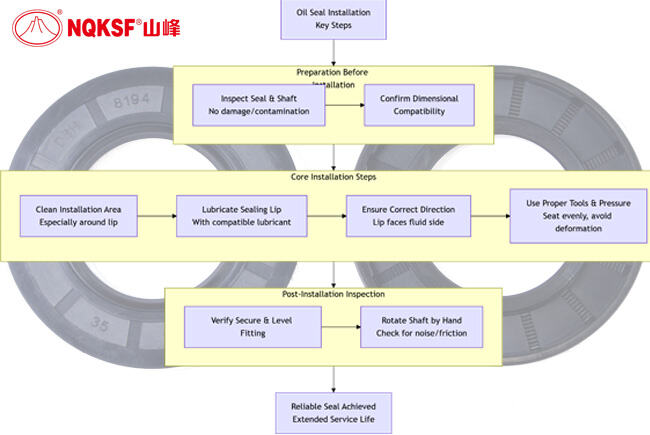

Ullmhúchán Roimh A shuiteáil

Scag scéal Oile

Laghdú nach bhfuil craiceanna nó athshainmhíniú ar lip an tsiabhra agus go bhfuil an spriong slán. Cuir an siabhrán in áit dá mbeadh aon eisiacht aimsithe.

Fíoraigh méid theastaíochta

Caithfidh trastomhas an aisse agus cró an tí a mheaitseáil le sonrúchán an tsiabhra ola. Mí-mheaitseáil, go háirithe rómholmhara nó rógearr, a dhéanfaidh dochar don fheidhmíocht siabhraithe.

Glan uilig dhromchla teagmhála

Caithfidh an as, agus an cró a bheith saor ó bhurraí, fiúscanna ola, agus gáthghníomha. Is féidir le truailleadh greamú ar lip an tsiabhra nó feidhmíocht an tsiabhraithe a laghdú.

Coinnigh Timpeallacht Ghlan Suiteála

Caithfidh an limistéar suiteála a bheith saor ó thoirch agus asraic, go háirithe timpeall an chúinsí teagmhála síocháin. Féadfaidh giotáin bheaga ar nós plúr nó coscanna miotail teacht isteach ar an earradh sin, tréigthe a luascadh, agus saol seirbhíse a ghortú.

Teicnící Easacha Le linn Suiteála

Úsáid uirlisí cearta

Cuidíonn uirlisí speisialta le haghaidh shuiteála sínghlúine le brú comhionann a chur i bhfeidhm agus mí-aimhlíneáil a chosc.

Más mian leat na huirlisí seo a bheith ar fáil, is féidir cluasach rúbair agus cál treoracha a úsáid, ach nárna builleodh an sín go díreach riamh.

Cuir smurgadh ar

Smurgadh an lip síocháin le hinneall nó le greasa atá совtháite leis an meán chóras chun friction tosaigh a laghdú.

Sínghlúin le casadh airgeadaigh: sheachain smurgadh an taobh amach chun imeacht a chosc

Sínghlúin le casadh rúbair: cabhróidh clúdach éadon le cuireadh isteach

Dearbhaigh treo suiteála

Caithfidh an béal sìoláideála a dhreapáil an meán a shíolálfar. Cuirfidh míshuimeáil chomh maith le neamhspleáchas sìoláideála i bhfeidhm láithreach.

Seiceáil doimhneacht suiteála

Brúigh an sìoláid go ciún go dtí an suíomh deartha. Ná brú ró-mhór, mar d'fhéadfadh brú casta an béal a chruthbhriseadh nó an sprionn a scaoileadh.

Seic Dhiúlta Seirbhíse

Laghdaigh go mbeidh an sìoláid cothrom gan bhearta ardaithe nó easumhoireacht.

Rothlaigh an seafta de láimh chun a dheimhniú nach bhfuil aon cheangal ná frithchuimilt neamhghnácha ann.

Más féidir, déan triail ghearr chun seiceáil le haghaidh sciorrachta nó fuaim ea-ghnácha.

D'fhéadfadh sìoláidí oighear a bheith beaga, ach tá ról suntasach agat orthu. Ní fhreastalaíonn suiteáil cheart amháin ar sciorradh a chosc, ach síneann sé saoil na n-inneal. Tógáil próisis stándardaithe suiteála agus soláthar oiliúint rheoirlithe do thionscailíní a laghdaíonn go mór neamhspleáchais sìoláideála i mbainistiú laethúil.

Nuacht Thuath

Nuacht Thuath