בתחום פתרונות החותמים הדינמיים, ה חותם מים VA/VS סדרת אטמים אלו, שתוכננה במיוחד עבור יישומים בהם אלמנטים סביבתיים ותנועה מכנית מצטלבים, חיוניים לשמירה על יציבות ואורך חיים של מכונות מסתובבות. בין אם משמשים במערכות טיהור מים תעשייתיות או ביחידות ייצור חשמל, אטמי VA ו-VS בנויים כדי לשרת צרכים קריטיים של ביצועים בתנאי עבודה מאתגרים.

דיוק בעיצוב, מומחיות בביצועים

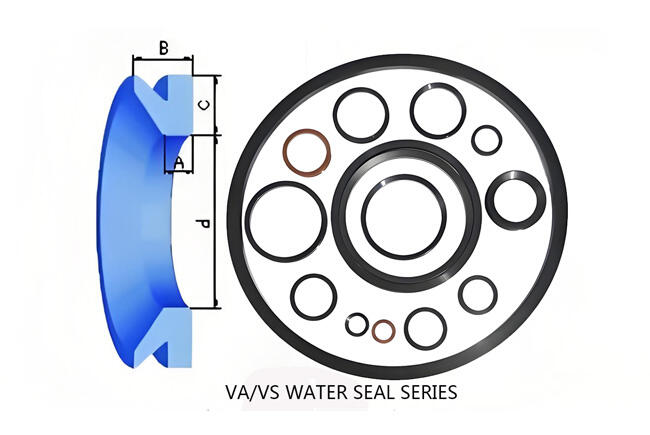

הסדרה VA נועדה בדרך כלל עם פרופיל שפם בודד והיא בשימוש נרחב בסביבות שדורשות הגנה מתונה מפני אבק ומריחות. לעומת זאת, הסדרה VS מציגה תצורת שפם כפולה שמאפשרת יעילות חותם מוגזמת - במיוחד מתאימה למים אגרסיביים יותר או סביבות מריחות שמן. שתיהן משתמשות במשולב של חומרי אלסטומר גמישים וטבעת מתכת מבנית כדי לשמור על קשר הדוק תחת תנועה סיבובית.

חותמים אלו מיוצרים לרוב מ-NBR ( каучוק ניטרילי) להתנגדות כללית למים ושמן, ו-FKM (فلואורו каучוק) לסביבות טמפרטורה וכימיקלים גבוהה יותר. בחירת החומר תלויה בתנאי הפעולה כגון לחץ, סוג נוזל, טמפרטורה, ומהירות ציר.

שימוש ת scope של סדרת חותמי המים VA/VS

חותמי המים מסוג VA/VS אינם רכיבים כלליים - הם משרתים מטרה ברורה במערכות שבהן r. היישומים השכיחים ביותר כוללים:

· משאבות מים ומערכות טיהור

· מנועים חשמליים שנחשפים לחות או לסביבות קשות

· תיבת הילוכים בסביבות פעולה כבדות או רטובות

· ציוד כביסה תעשייתי

· מכשורים חקלאיים עם חשיפה חוזרת של מים

· טורבינות רוח ומערכות גלגיל בת sector האנרגיה

· ציוד בנייה וمركبات שטח

על ידי מניעת זיהום וליקויים פנימיים, החותמים הללו מביאים תפקיד חשוב בהפחתת זמני השבתה ובחסינת אורך חיי השירות, במיוחד במגזרים בהם זמני פעילות ישירים ישפיעו ישירות על ייצוריות.

מי צריך חותמי מים VA/VS?

המשתמשים הסופיים של חותמי VA/VS פזורים לאורך מגוון רחב של תחומים. אך הרלוונטיות שלהם בולטת במיוחד ב:

· יצרני טיפול במים ו펌פות

· יצרני ציוד חקלאי OEM

· מונטאז'נים של מנועים חשמליים

· יצרני תיבת הילוכים ומנחילי מהירות

· טכנאי תחום האנרגיה הרוחנית והמקורות המתחדשים

· יצרנים בقطاع הבנייה והכלי רכב מחוץ לכביש

· אנשי מקצוע בתחזוקה תעשייתית למכונות מסתובבות

משתמשים אלו priorize קיימנות, נוחות בהתקנה, ותאימות לתנאי פעולה אגרסיביים או רטובים – כל התחומים בהם סדרת ה-VA/VS מציגה ביצועים חזקים.

התאמה אישית ואופטימיזציה של חומרים על ידי NQKSF

אחת המאפיינים המרכזיים של המותג NQKSF היא ההתחייבות לפתרונות חותם מותאמים אישית. בעוד שחותמים סטנדרטיים של VA/VS זמינים למשלוח מיידי, NQKSF מציעה שירות התאמה מלא המכיל:

ייעוץ בחומרים לבחירת NBR, FKM, EPDM, או תבניות פולימר מותאמות אישית, בהתאם לתווך הטמפרטורה והמצבים הספציפיים

תמיכה בעיצוב המבני עבור גוף לא סטנדרטי או תצורות ציר

יצירת דגם מהיר וביצוע בדיקות ביצועים, מאפשרת ללקוחות לאמת את הביצועים בתנאי עבודה סימולטיביים

התמיכה בטווח מלא זה מבטיחה בחירת החֹתֶמֶת הנכונה ליישום כל אחד, מפחיתה את הסיכון לכישלון עקב אי התאמה סביבתית או אי תאימות מכאנית.

לוגיסטיקה, זמינות ומכסה גלובלית

NQKSF פועלת ממסגרת ייצור חכמה שמאחוריה עומדים למעלה מ-30 שנה של חותמת. עם אלפי חלקים סטנדרטיים, כולל טבעות חניקה, חותמות שמן, וחותמות מים VA/VS, החברה מובילה שבמרכזי הביקוש הגבוהים תמיד במלאי ומזומנים למשלוח מהיר. יכולת זו מאפשרת ללקוחות תעשייתיים להגיב במהירות לצורכי תחזוקה או ייצור דחופים.

כספק מוסמך בתעשייה החותמת, טווח השפעת NQKSF כולל מעל 80 מדינות, והוא תומך הן ביצרני ציוד מקוריים מוכרים והן בשווקים עולים. החברה זכתה גם בכינויים מרכז חדשנות ברמת המחוז, ישות הייטק, וכשחקן מוביל באשכולות חותמות מהתמחות—כינויים המבטאים את עומק הידע הטכנולוגי שלה ואת מנהיגותה בשוק.

שיפור מערכות באמצעות מומחיות טכנית

ביצועי החותם אינם קשורים רק לגומי - אלא לשלמות למערכת שלמה. NQKSF מציעה לשراים שלה ייעוץ טכני כדי:

· אופטימיזציה של עיצוב החותם לשם הפחתת החיכוך ועמידה בפני בלאי

· שיפור דינמיקת הנוזלים בממשק הציר

· הארכת הזמן הממוצע בין תחזוקות (MTBM)

· זיהוי הזדמנויות לחיסכון בעלות באמצעות שדרוג חומרים או שיפורים בעיצוב

באמצעות יישום של עשורים של ידע שטחי, NQKSF מחזיקה את הלקוחות שלה לשפר את היעילות, להפחית את עלות הבעלות הכוללת ולשמור על ביצועים עקביים בתנאי עבודה קשים.

סדרת החותמים VA/VS היא יותר מרק רכיב מכאנלי - זהו אלמנט אסטרטגי בשמירה על ציוד תעשייתי מפני הטבע הלא-ניבאתי של מים, אבק ולחצי סיבוב. לייצרנים ומהנדסי תחזוקה, בחירת החותם הנכון - נתמך בעיצוב מקצועי, אספקה מהירה ואפשרויות חומרים מוכחות - יכול לספק הבדל משמעותי בזמן התפעלה ובביצועים.

חדשות חמות

חדשות חמות