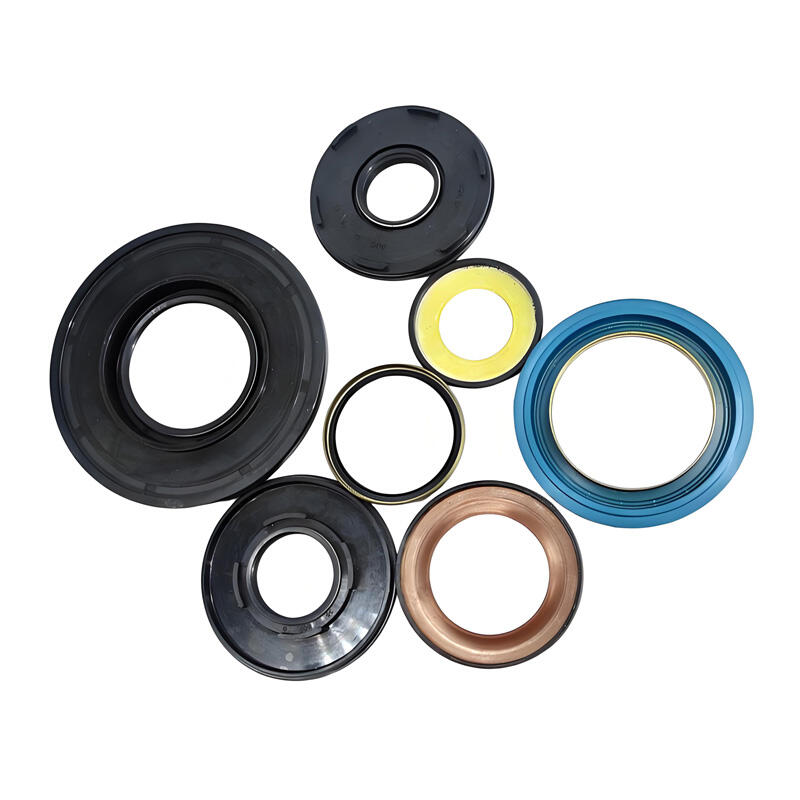

rubber oil seals manufacturers

Rubber oil seal manufacturers play a crucial role in modern industrial applications by producing essential components that prevent fluid leakage and contamination in mechanical systems. These manufacturers specialize in designing and producing high-quality seals that maintain system integrity across various operating conditions. Using advanced manufacturing processes and state-of-the-art technology, they create seals that effectively contain lubricants while keeping harmful contaminants out. The manufacturing process involves careful material selection, precision molding, and rigorous quality control measures to ensure each seal meets exact specifications. These manufacturers typically offer a wide range of products, from standard oil seals to custom-designed solutions for specific applications. Their products incorporate various rubber compounds, including nitrile, silicone, and fluorocarbon, each selected for specific performance characteristics. The seals are engineered to withstand extreme temperatures, chemical exposure, and high-pressure environments while maintaining their sealing properties. Modern manufacturers also employ advanced testing facilities to verify seal performance under simulated operating conditions, ensuring reliability and longevity. They serve diverse industries, including automotive, aerospace, industrial machinery, and heavy equipment sectors, providing critical components that contribute to equipment efficiency and operational safety.