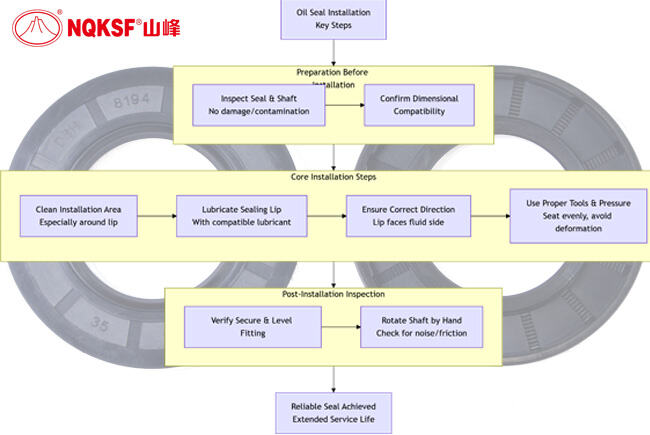

As someone working on the front line of sealing‑technology support, I have found that many cases of oil leakage or sealing failure are not caused by the oil seal itself, but by overlooked details during installation. The following practical recommend...

Read More

In low-temperature applications such as robot shaft systems, skeleton oil seals (radial shaft seal) frequently experience oil leakage, increased start–stop wear, and unstable sealing performance. Field experience shows that these failures are o...

Read More

Industrial robots operate under high precision and high load conditions, making the sealing performance of each joint critical. When the joint shaft undergoes ±180° reciprocating rotation, traditional sealing concepts face significant chal...

Read More

In robotic vision systems, lens cleanliness directly determines imaging quality. Yet many engineers overlook a critical detail: extractables from sealing O‑rings can contaminate the optical surface. To address this issue, three aspects must be consid...

Read More

To ensure the sealing stability of O-rings used in vacuum suction cups for sorting robots, multiple factors need to be considered. Below is a concise overview based on practical applications. First, material selection is critical. Wear-resistant and ...

Read More

In the field of industrial automation, the sealing system of palletizing robot gripper cylinders plays a crucial role in ensuring the efficient and stable operation of the equipment. Especially in environments with frequent reciprocating motion, the ...

Read More

The model designation and selection of skeleton oil seals are not as complicated as they may seem. Most naming conventions follow GB/T 9877, ISO 6194, and common industry practices. A typical model format is: Type – (Inner Diameter × Oute...

Read More

When assessing the quality of skeleton oil seals, two main aspects should be considered: appearance and performance. Below are commonly accepted standards. Appearance Inspection Surface Quality: A high-quality oil seal should have a smooth, even sur...

Read More

The shelf life of a skeleton oil seal is typically three to five years for NBR (nitrile rubber) materials and five to eight years for FKM (fluororubber) materials. During storage, temperature, humidity, light exposure, and ozone levels must be contro...

Read More

In sealing systems, the skeleton oil seal (also known as a rotary shaft seal) plays a critical role. It must not only prevent the leakage of lubricants but also block the intrusion of external contaminants such as dust and moisture. While many believ...

Read More

In industrial equipment, automotive manufacturing, and motor transmission systems, skeleton oil seals serve as critical rotary shaft sealing components. They prevent lubricant leakage and block external contaminants—functions essential to equip...

Read More

If you’re looking for dependable skeleton oil seal suppliers, here is a curated list of reputable manufacturers from both international and domestic markets. You can choose the right partner based on your equipment needs, budget, and applicatio...

Read More Hot News

Hot News