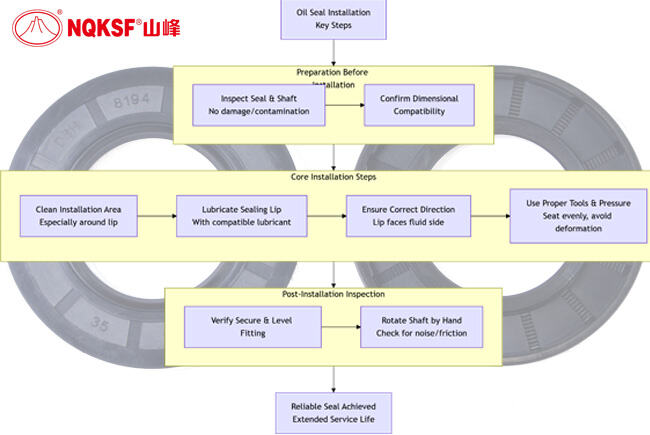

بصفتي شخصًا يعمل في الخطوط الأمامية لدعم تقنيات الختم، وجدت أن العديد من حالات تسرب الزيت أو فشل الختم لا تُسببها طوقاية الزيت نفسها، بل بتفصيلات يتم تجاهلها أثناء التركيب. التوصيات العملية التالية...

قراءة المزيد

في التطبيقات ذات درجات الحرارة المنخفضة، مثل أنظمة أعمدة الروبوتات، تتعرض موانع التسرب الزيتية الهيكلية (مانع التسرب المحوري) بشكل متكرر لتسرب الزيت، وزيادة التآكل الناتج عن التشغيل والإيقاف، وعدم استقرار أداء منع التسرب. وتشير التجارب الميدانية إلى أن هذه الأعطال...

قراءة المزيد

تعمل الروبوتات الصناعية في ظروف دقة عالية وحمل عالٍ، مما يجعل أداء الختم في كل مفصل أمرًا بالغ الأهمية. وعندما يدور العمود المفصلي بشكل ترددي بزاوية ±180°، تواجه المفاهيم التقليدية للختم تحديات كبيرة...

قراءة المزيد

في أنظمة الرؤية الروبوتية، يتحدد جودة التصوير مباشرةً بناءً على نظافة العدسة. لكن كثيرًا من المهندسين يغفلون عن تفاصيل حرجة: المواد القابلة للانسحاب من حلقات الأختام المانعة قد تتسبب في تلوث السطح البصري. ولحل هذه المشكلة، يجب أخذ ثلاثة جوانب بعين الاعتبار...

قراءة المزيد

لضمان استقرار الختم لحلقات O المستخدمة في كؤوس الشفط بالفراغ للروبوتات الفارزة، يجب أخذ عوامل متعددة بعين الاعتبار. فيما يلي نظرة عامة موجزة بناءً على التطبيقات العملية. أولاً، اختيار المادة أمر بالغ الأهمية. تُستخدم عادةً مواد مطاطية مقاومة للتآكل ومرنة للغاية مثل NBR (المطاط النتريلي) وFKM (الإيلاستومر الفلوري). يمكن لهذه المواد الحفاظ على أداء ختم موثوق به ضمن نطاقات درجات حرارة مختلفة والبيئات الكيميائية، مما يضمن شفطًا ثابتًا بالفراغ أثناء التشغيل.

قراءة المزيد

في مجال الأتمتة الصناعية، تلعب نظام الختم الخاص بأسطوانات مقابض الروبوتات التحميلية دورًا حيويًا في ضمان التشغيل الفعّال والمستقر للمعدات. وخصوصًا في البيئات التي تتسم بحركة ترددية متكررة، فإن اختيار المادة الخاصة بالحشوات الدائرية...

قراءة المزيد

إن تسمية واختيار نماذج الأختام الزيتية الهيكلية ليست معقدة كما قد تبدو. تتبع معظم الاصطلاحات التسمية المعيار GB/T 9877، ISO 6194، والممارسات الصناعية الشائعة. يكون التنسيق النموذجي لنموذج ما عادةً كالتالي: النوع – (القطر الداخلي × القطر الخارجي...

قراءة المزيد

عند تقييم جودة الأختام الزيتية العظمية، يجب النظر في جانبين رئيسيين: المظهر والأداء. فيما يلي المعايير المقبولة بشكل شائع. فحص المظهر جودة السطح: يجب أن يكون الختم الزيتي عالي الجودة ذو سطح ناعم ومتساوٍ دون شوائب أو تشققات أو فقاعات أو شوائب مدمجة. يجب أن يظهر المطاط بلون موحد، ويجب أن يكون الإطار المعدني خالياً من الصدأ، ويجب أن يكون شفاه الختم (الحافة) حادة ومتساوية وبدون تقطيع.

قراءة المزيد

يبلغ العمر الافتراضي لختم زيت الهيكل العظمي عادةً من ثلاث إلى خمس سنوات للمواد المصنوعة من مطاط النتريل (NBR) ومن خمس إلى ثماني سنوات للمواد المصنوعة من المطاط الفلوري (FKM). أثناء التخزين، يجب التحكم في درجة الحرارة والرطوبة وكمية التعرض للضوء ومستويات الأوزون...

قراءة المزيد

في أنظمة الختم، يلعب الختم الزيتي الهيكلي (المعروف أيضًا باسم ختم العمود الدوراني) دورًا حيويًا. فهو لا يمنع فقط تسرب المواد التشحيمية، بل ويحول دون دخول الملوثات الخارجية مثل الغبار والرطوبة. وبينما يعتقد كثير من الناس أن أداء الختم يعتمد بشكل رئيسي على مادة التصنيع وتصميم البنية، فإن السر الحقيقي يكمن في آلية الختم عند الشفة وفي التصميم المناسب للمطابقة بالضغط.

قراءة المزيد

في المعدات الصناعية، وتصنيع السيارات، ونظم نقل الحركة المحركية، تعمل الختميات النفطية الهيكلية كمكونات حيوية لإغلاق الأعمدة الدوارة. حيث تمنع تسرب المواد التشحيمية وتوقف الشوائب الخارجية—وظائف ضرورية لتجهيز...

قراءة المزيد

إذا كنت تبحث عن موردين موثوقين لخراطيش الختم الزيتي العظمية، فإليك قائمة تم اختيارها بعناية من الشركات المصنعة ذات السمعة الطيبة من الأسواق الدولية والمحلية. يمكنك اختيار الشريك المناسب وفقًا لاحتياجات معداتك، وميزانيتك، وتطبيق...

قراءة المزيد أخبار ساخنة

أخبار ساخنة