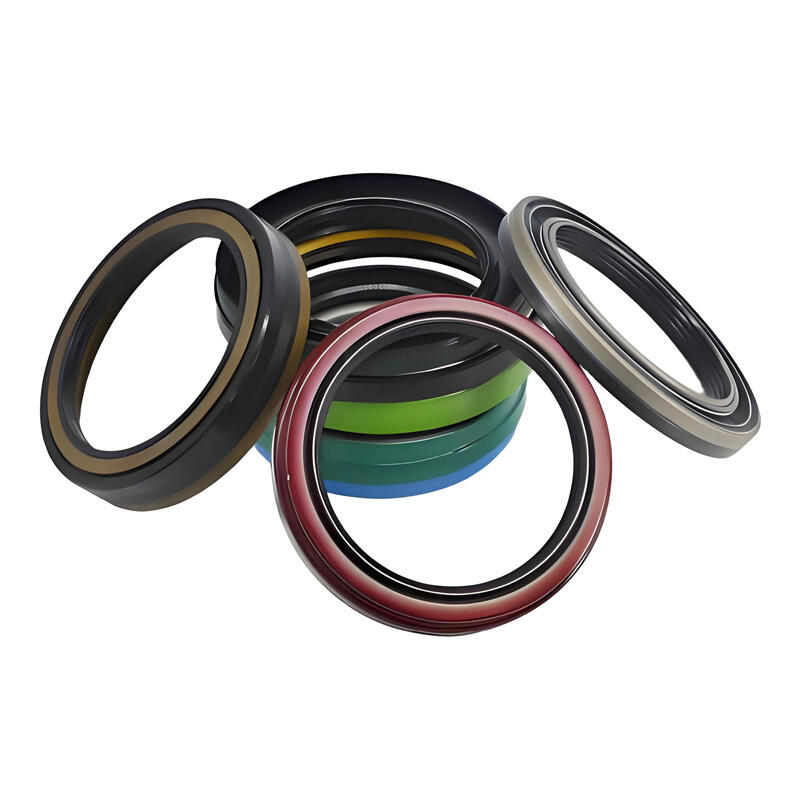

silicone o rings

Silicone O rings represent a crucial component in modern sealing technology, serving as versatile and reliable sealing solutions across numerous industries. These circular sealing elements are manufactured from high-quality silicone rubber, offering exceptional resistance to extreme temperatures ranging from -60°C to 200°C. The unique molecular structure of silicone provides these O rings with outstanding compression set resistance and remarkable elastic recovery properties, ensuring consistent sealing performance over extended periods. Their design incorporates precise dimensional tolerances and smooth surface finishes, enabling them to create effective barriers against liquids, gases, and environmental contaminants. These O rings maintain their flexibility and sealing capabilities across a wide range of operating conditions, making them particularly valuable in dynamic applications where traditional rubber materials might fail. The material composition also provides excellent resistance to ozone, UV radiation, and various chemical compounds, contributing to their long service life and reliability in demanding environments. Their applications span across automotive, aerospace, medical devices, food processing equipment, and industrial machinery, where maintaining seal integrity is paramount for operational safety and efficiency.