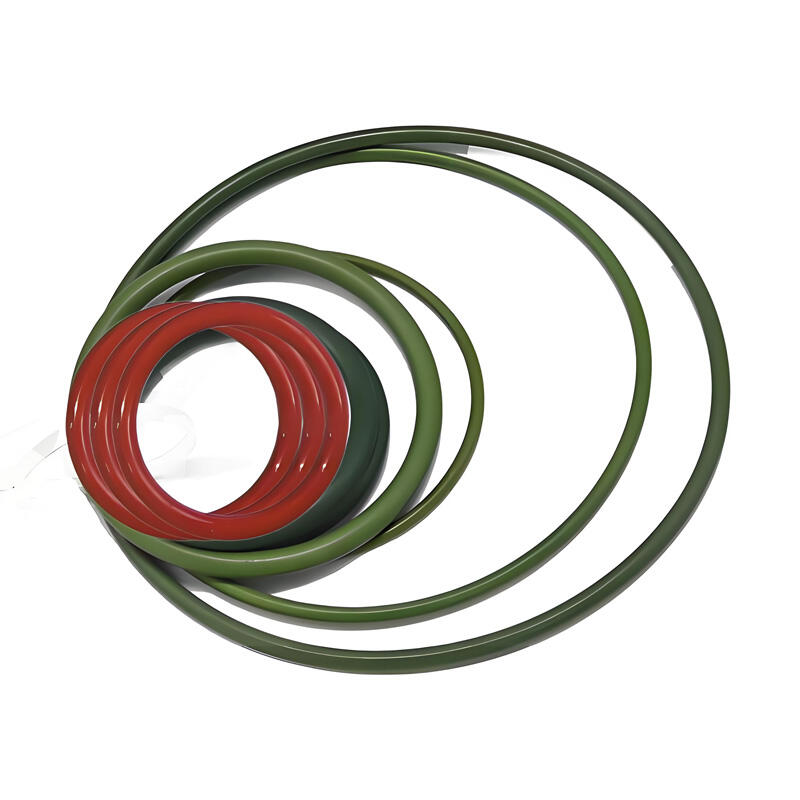

vs seal

The VS seal represents a significant advancement in industrial sealing technology, designed to provide superior protection against fluid leakage in various mechanical applications. This innovative sealing solution combines robust materials with precision engineering to create a reliable barrier against both liquid and gas penetration. The VS seal features a unique V-shaped profile that enables it to maintain consistent contact pressure even under varying operating conditions. Its design incorporates advanced elastomeric compounds that offer exceptional resistance to temperature extremes, chemical exposure, and mechanical stress. The seal's dynamic response mechanism automatically adjusts to wear and pressure changes, ensuring sustained performance throughout its operational life. In industrial applications, the VS seal proves particularly valuable in rotating equipment, hydraulic systems, and pneumatic devices where maintaining seal integrity is crucial. The seal's versatility allows it to function effectively in both static and dynamic applications, making it an ideal choice for diverse industrial scenarios. With its self-adjusting properties and durable construction, the VS seal significantly reduces maintenance requirements and extends equipment service life. The seal's innovative design also accommodates shaft misalignment and surface irregularities, providing reliable sealing even under challenging conditions.