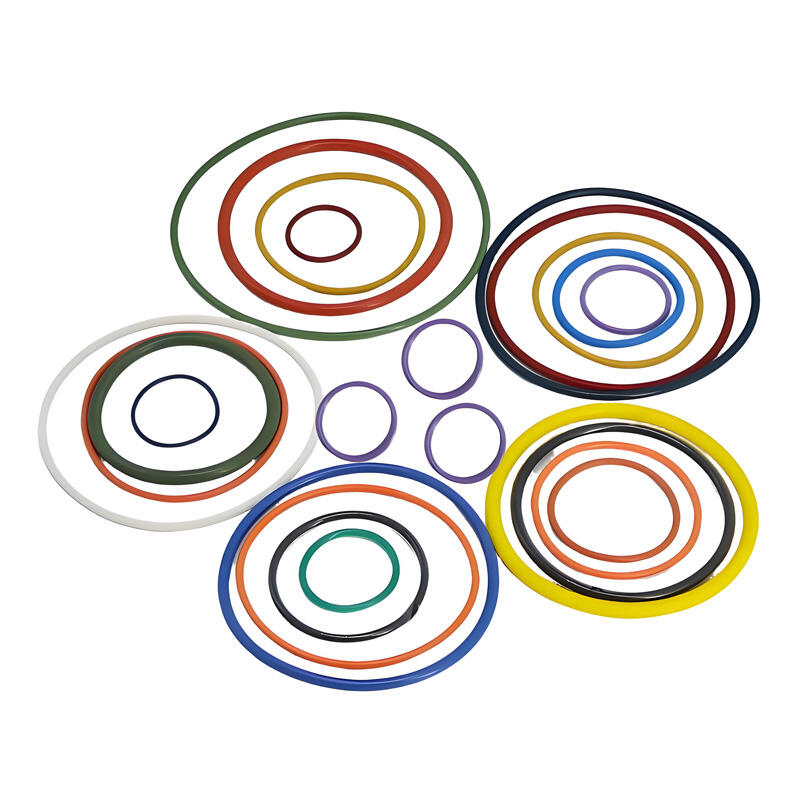

wheel oil seal

A wheel oil seal is a crucial mechanical component designed to prevent oil leakage and protect against external contaminants in rotating machinery, particularly in vehicle wheel assemblies. This precision-engineered device consists of multiple layers, typically featuring a robust metal case and a flexible elastomeric sealing lip. The primary function of a wheel oil seal is to maintain proper lubrication by keeping essential oils and greases within the wheel hub assembly while simultaneously preventing the ingress of harmful elements such as dust, water, and debris. The seal's design incorporates advanced materials and manufacturing techniques to ensure optimal performance under various operating conditions, including extreme temperatures and high-speed rotation. Modern wheel oil seals often feature specialized lip designs that create multiple sealing points, enhancing their effectiveness in maintaining a clean and well-lubricated environment for bearings and other critical components. The technology behind these seals has evolved significantly, with many now incorporating additional features such as integrated sensors for monitoring seal wear and performance. In industrial applications, wheel oil seals play a vital role in extending equipment life and reducing maintenance costs across various sectors, from automotive to heavy machinery.