Bearings fail not only because of load or fatigue, but also because the lubricant escapes or contaminants enter. This is where the bearing seal quietly determines how long a machine will keep running.

Bearing seal has one simple mission: keep the inside clean and the outside out. That may sound straightforward, but the environments in which these seals operate are anything but simple. In the hub of a heavy truck, the seal must hold back mud, water, and high-speed rotation. In an industrial motor, the same type of component is expected to survive thousands of hours with minimal friction and almost no heat generation. The diversity of tasks explains why bearing seals come in so many forms, and why choosing the right one is not a matter of browsing a catalog page but understanding real working conditions.

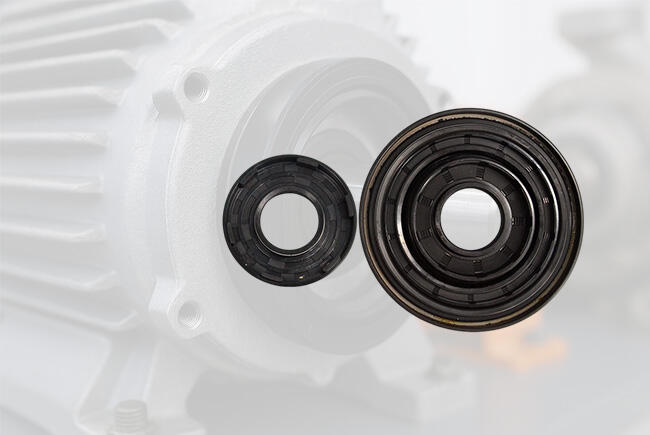

If we look at types, there are designs that press against the bearing surface to make a tight barrier. These are often chosen when dirt, dust, or liquid contamination is the biggest enemy. Farmers relying on tractors, for example, cannot afford seals that let dust slip through. On the other side, there are seals designed to avoid contact; they let the bearing run fast without extra drag. High-speed electric motors or precision instruments typically rely on these. Many buyers discover that the right choice is not about which type is “better,” but about which type fits the specific balance of cleanliness, speed, and energy efficiency.

Materials are another area where experienced buyers pay attention. Standard rubber like nitrile (NBR) is affordable and good for everyday industry needs, but when temperatures climb or chemicals become aggressive, something stronger is required. Fluoroelastomers (FKM) handle automotive engines and chemical plants with more resilience. PTFE is used when machines run extremely fast or when friction must be kept to a minimum.

Industries that depend on bearing seals are wide-ranging. Obvious sectors like automotive, industrial gearboxes, and pumps come first to mind. But more recently, demand has grown in renewable energy, particularly wind turbines, where climbing up to replace a failed seal can cost tens of thousands. Robotics is another field: seals for robotic arms need to combine precision, flexibility, and long life. Rail transport and aerospace also present their own challenges, where long maintenance intervals require seals that can survive without attention for years. For distributors and OEM procurement managers, knowing these sector differences can shape inventory strategy and strengthen customer trust.

At this point, many buyers ask the same questions: How fast can I get the seals I need? Can the supplier help if my application is unusual? Will the quality be consistent if I order in bulk? These are not academic concerns—they are the daily issues that decide whether a distributor retains its customers. The answer often lies in whether the supplier combines broad catalog coverage with the ability to customize. A brand like NQKSF, for example, has earned recognition by managing both ends: tens of thousands of standard specifications ready for immediate shipment, and a complete customization service that starts with material selection, continues through design and testing, and finishes with delivery that fits the working condition precisely. For urgent repairs, the ready stock saves downtime; for complex projects, the tailored approach secures long-term reliability.

NQKSF is credibility also rests on more than just product. With more than thirty years of experience in the sealing field, it acts as a technical partner. Many procurement managers mention that the real value lies in guidance—being advised on how to optimize sealing systems, reduce maintenance costs, and prevent repeat failures. It is also reassuring for global buyers that the company is not a trading intermediary but a manufacturing-based enterprise with recognition as a provincial innovation center, a specialized and innovative company, and part of a leading industrial cluster. With seals sold to more than 80 countries, NQKSF has become a familiar name in the international market, supported by a reputation built on reliability rather than promises.

For distributors, wholesalers, and OEM buyers reading this, the takeaway is simple: the bearing seal is small but decisive. It determines whether your end users see smooth production or repeated breakdowns. When selecting partners, do not only look at the catalog page. Look for suppliers who can move quickly with standard parts, respond flexibly with custom solutions, and stand behind their products with technical expertise. Those who align with such manufacturers find that their own reputation grows, because they deliver not only parts but also reliability.

In today is competitive market, the companies that win are not those with the lowest prices alone, but those who build trust by solving real problems quickly and consistently. Brands like NQKSF, with stock readiness, technical depth, and global reach, are setting a benchmark for what it means to be a reliable sealing partner in modern industry.

Hot News

Hot News