For distributors and wholesalers serving the automotive, heavy truck, and rail sectors, the wheel hub seal is a product category that demands both technical reliability and supply chain consistency. A single seal failure can lead to costly downtime, but a supply gap can be just as damaging to customer relationships. That’s why sourcing from a manufacturer with both engineering depth and logistical strength is essential.

Wheel hub seal is primary job is twofold:

· Keeping lubricants inside the hub assembly to ensure smooth bearing operation.

· Blocking contaminants such as water, dust, and road debris from entering the bearing cavity.

In high-mileage fleets, seals must endure constant rotational speeds, temperature fluctuations, and exposure to chemicals like de-icing agents. The right seal design can extend service intervals and reduce total cost of ownership.

Key Design Considerations for Buyers

When evaluating wheel hub seals for your catalog, consider:

· Lip Configuration: Multi-lip designs offer enhanced protection in severe environments.

· Material Compatibility: Match elastomer type to the operating temperature and chemical exposure.

· Ease of Installation: Unitized designs reduce the risk of damage during assembly, lowering return rates.

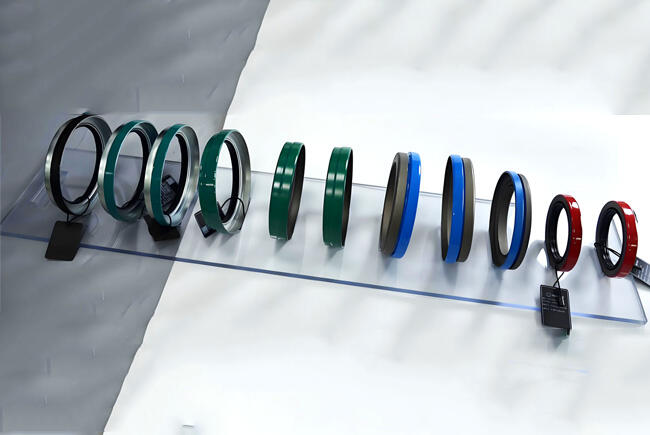

Material Options

· NBR: Cost-effective, oil-resistant, suitable for moderate temperatures.

· FKM: High-temperature and chemical resistance for demanding applications.

· PTFE: Low friction, excellent wear resistance, ideal for high-speed or dry-running conditions.

Wheel hub seals are indispensable in:

· Automotive and heavy truck manufacturing

· Rail transport

· Construction and mining vehicles

· Agricultural machinery

· Aerospace ground support equipment

FAQ

Q: How can I ensure consistent quality across large orders?

A: Partner with a manufacturer with in-house production and testing facilities, ensuring every batch meets the same standards.

Q: What’s the advantage of stocking standard sizes?

A: Immediate availability reduces lead times for your customers, improving satisfaction and repeat business.

Q: Can I get private-label seals?

A: Yes, with the right supplier, branding can be integrated into the manufacturing process without compromising performance.

NQKSF: Your Strategic Partner

· Standard parts, fast delivery: Covering O-rings, oil seals, and more than 10,000 specifications with ample stock to meet urgent needs.

· End-to-end customization: From selecting the right material to final testing, ensuring seals are tailored to your market’s demands.

· Technical expertise: Over 30 years of experience helping clients improve sealing performance, cut maintenance costs, and boost equipment reliability.

With a fully equipped manufacturing facility, status as a leader in the sealing industry, and a product range that ships to 80+ countries, NQKSF is recognized as a global brand and holds distinctions such as Provincial Technology Innovation Center, Specialized and Innovative Enterprise, High-Tech Enterprise, and Leading Company in a Specialized Industrial Cluster. For distributors and wholesalers, this means a partner who understands both the technical and commercial sides of the sealing business.

Hot News

Hot News