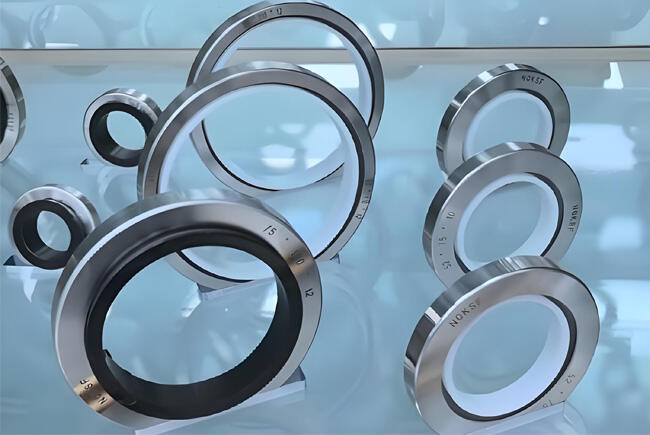

In many industrial settings, the integrity of your system depends on the smallest components doing their job without fail. Seals, in particular, play a silent yet critical role—keeping fluids contained, contaminants out, and operations running without interruption. For conditions that push materials to the limit, NQKSF offers a solution built for endurance: stainless steel-reinforced PTFE seals.

Stainless steel PTFE seals are not designed for the average application. They're developed for situations where ordinary seals deform, degrade, or simply give out. Whether it’s exposure to aggressive chemicals, fluctuating temperatures, or high-pressure environments, this series delivers dependable sealing performance when it matters most.

Why PTFE Stainless Steel Shaft Seals?

PTFE (Polytetrafluoroethylene) has long been a go-to material in sealing due to its remarkable chemical resistance and low friction. But in high-stress environments, PTFE alone may not offer the structural stability required. That’s where stainless steel reinforcement comes in.

By integrating precision-formed stainless steel cores—typically in 304 or 316 grade—we combine the flexibility and inertness of PTFE with the strength and rigidity needed for high-pressure or mechanically demanding setups. The result is a robust sealing element that holds its form under stress while maintaining all the advantages of PTFE.

Applications Across Critical Industries

Stainless steel PTFE shaft seals are commonly used in industries where downtime is costly and safety is non-negotiable:

· Chemical and petrochemical plants – For pipelines, valves, and reactors handling corrosive fluids.

· Aerospace and automotive – In systems exposed to thermal shock, vibration, or high rotational speeds.

· Power generation – Steam turbines, pumps, and compressors that face continuous pressure cycling.

· Pharmaceutical and food equipment – Applications requiring both chemical inertness and hygiene compliance.

Tailored to Perform

We don’t believe in one-size-fits-all solutions. That’s why our stainless steel-reinforced PTFE seals come in multiple configurations:

· Spring-energized lips for variable pressure conditions

· Flanged and V-ring styles for axial loads

· Custom lip geometries for specific dynamic sealing requirements

Key performance metrics include:

· Operating temperature: -65°C to +260°C (higher upon request)

· Pressure tolerance: Up to 40 MPa (static or low-speed dynamic)

· Chemical compatibility: Resistant to most acids, solvents, fuels, and high-temperature steam

Wear resistance: Outstanding longevity in abrasive or high-cycle environments

The NQKSF Difference

What sets NQKSF apart isn’t just the materials we use—it’s how we work with our clients. With over three decades of expertise in sealing technology, we support everything from prototype development to volume production.

· Over 10,000 part numbers in stock, including standard O-rings, oil seals, and customized designs

· Fast delivery from our extensive domestic inventory

· Certified R&D team with simulation, testing, and material analysis capabilities

· Global customer base in over 80 countries

We understand that every system has its own challenges. That’s why we offer engineering support from day one—helping you choose the right seal based on real-world conditions, not just specs on paper.

If your system operates in an environment where failure is not an option, consider upgrading to NQKSF is stainless steel-reinforced PTFE seals. Backed by deep engineering knowledge and reliable production, PTFE seals series are built to handle whatever your machinery throws at them.

Hot News

Hot News