In modern automation and precision-driven industries, pneumatic seals play a critical role in ensuring the reliability and efficiency of air-powered systems. Designed to withstand friction, prevent leakage, and optimize energy consumption, the pneumatic sealing series by NQKSF has been engineered to meet evolving industrial needs. From robotic automation to precision assembly and beyond, these seals represent the silent yet vital component in maintaining operational stability.

Understanding Pneumatic Seals in Industrial Applications

Pneumatic seals are primarily used to contain compressed air or gas and prevent it from leaking between different machine components. They are often deployed in cylinders, valves, pneumatic actuators, and various pressure-regulated systems. Unlike hydraulic systems, which rely on oil-based fluids, pneumatic systems use air, making cleanliness and leakage resistance key priorities for sealing solutions.

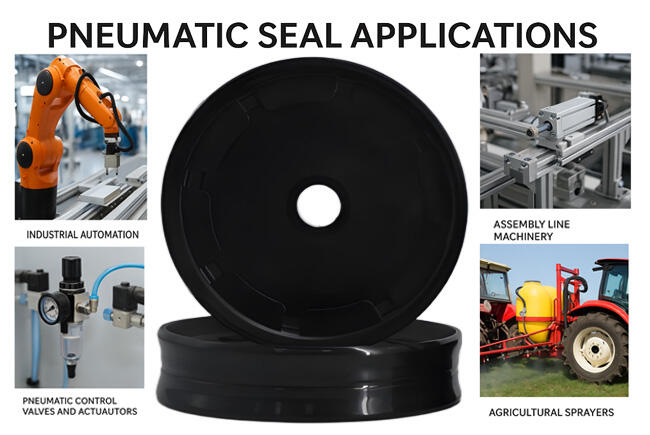

Common Applications Include:

· Robotic Arms and Automation Equipment

· Pneumatic Control Valves and Actuators

· Assembly Line Machinery

· Textile and Packaging Machines

· Industrial Braking Systems (using air pressure)

· Aircraft Cabin Control Systems

· Agricultural Pneumatic Sprayers

Pneumatic seals are essential for reducing wear, preventing contamination, and ensuring precise motion control.

Tailored Material Options for Various Demands

The NQKSF pneumatic seal series offers a selection of materials adapted to different industrial requirements:

· NBR (Nitrile Rubber): Suited for standard air-pressure operations with excellent abrasion resistance.

· FKM (Fluorocarbon Rubber): Offers high chemical and temperature resistance for harsh environments.

Through advanced material selection, NQKSF helps manufacturers enhance system longevity and reliability across diverse conditions.

Service Innovation that Matches Your Needs

Backed by over 30 years of sealing expertise, NQKSF provides services that go beyond product supply:

Fast Delivery of Standard Components:

With an extensive inventory covering over 10,000 specifications of O-rings, oil seals, and pneumatic components, urgent needs are swiftly met with ready-to-ship items.

Full-Cycle Customization:

For applications beyond the standard, NQKSF offers end-to-end customization services. This includes material selection, design optimization, prototyping, and testing—ensuring the final product perfectly fits your mechanical environment.

Technical Support for Sealing Systems:

Leveraging deep industry insight, NQKSF provides consultation and support for optimizing sealing configurations. This improves performance, extends seal life, and reduces maintenance intervals.

Industrial Reliability Backed by Enterprise Strength

What truly sets NQKSF apart is its operational foundation and recognized leadership in sealing technology:

· In-house intelligent manufacturing base

· Comprehensive product catalog with immediate availability

· Supply footprint reaching over 80 countries

· Partner to globally recognized machinery brands

· Recognized as a Provincial Technology Innovation Center

· Holder of “Specialized and New Enterprise” designation

· Rated a High-Tech Enterprise

· Key player in local industrial seal cluster development

These strengths ensure not only product consistency and reliability but also flexibility in fulfilling diverse customer requirements.

Where Pneumatic Seals Make a Difference

The NQKSF pneumatic seal series is purpose-built for industries relying on air-driven mechanisms. Key sectors include:

· Automotive and Heavy Trucks (braking and air-suspension systems)

· Industrial Automation and Robotics

· Machinery for Food Processing and Packaging

· Agricultural Machinery (sprayers and pneumatic controls)

· Textile and Printing Equipment

· Energy and Wind Power Systems

· Aircraft Cabin and Interior Actuation Components

NQKSF is pneumatic seal series brings a valuable combination of technical resilience, customization, and trusted support. Whether for standard needs or tailored systems, NQKSF continues to deliver sealing components that quietly power innovation across industries.

Hot News

Hot News