Valve stem seals may be small, yet their importance in an engine cannot be overstated. Essentially, they control how much oil reaches the valve stem interface, lubricating the valve guide and helping to reduce engine emissions. This is true for both diesel and gasoline engines, whether naturally aspirated or turbocharged.

Designs and Materials

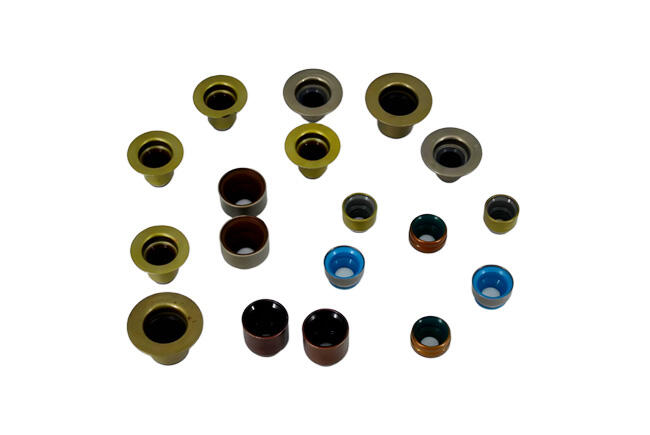

There are two main designs of valve stem seals:

· Non-integrated seals: Focus solely on oil metering. Simple but reliable.

· Integrated seals: Include a spring seat to reduce cylinder head wear. Very useful for high-load or long-running engines.

Some seals also feature a low-friction beaded lip, reducing power loss and friction while maintaining consistent oil flow. Material choice is key. Fluoroelastomers (FKM) handle high temperatures and aggressive oils, ideal for turbocharged engines. Nitrile (NBR) or other synthetics are more cost-effective for standard engines.

High-Pressure Applications

Engines with turbochargers or exhaust brakes face higher manifold pressures. Standard seals may deform or fail under these conditions. NQKSF’s high-pressure valve stem seals are designed to cope, maintaining precise oil metering and minimizing valve guide wear.

Industrial equipment like pumps, generators, and construction machines also rely on quality seals. Engines running under heavy loads or dusty environments can suffer from accelerated wear. Proper valve stem seals ensure reliable lubrication, extend maintenance intervals, and prevent unexpected downtime.

Distributors and OEMs care about several factors:

· Availability: Thousands of sizes are stocked, emergency orders fulfilled in 24–48 hours.

· Customization: Non-standard seals can be made to match engine specifics.

· Consistency: High-quality seals guarantee consistent oil metering across batches.

· Durability: Longer service life reduces valve guide wear and lowers long-term costs.

NQKSF is more than a manufacturer. Their services include:

· Immediate stock dispatch: O-rings, oil seals, valve stem seals ready to ship.

· Custom engineering: Material selection, design, and testing tailored to customer requirements.

· Technical support: Over 30 years’ experience optimizing sealing performance, reducing maintenance, and improving reliability.

The company operates a modern factory, is recognized as a provincial innovation center, and exports to over 80 countries. It is a high-tech, specialized enterprise, combining production capacity with technical expertise, making it a reliable partner for buyers.

Though small, valve stem seals have a significant impact on engine efficiency, emissions control, and durability. Choosing the right design, material, and supplier is critical. NQKSF offers extensive stock, customization, and expertise to help distributors, OEMs, and industrial users maintain engine performance, reduce maintenance, and ensure reliability across applications, including pumps, engines, industrial machines, construction equipment, and energy systems.

Hot News

Hot News