Steel manufacturing is one of the most demanding industrial sectors when it comes to equipment durability. The environment is intense: high temperatures, abrasive dust, corrosive chemicals and continuous mechanical stress. Every machine—from rolling mills and hydraulic cylinders to pumps, motors, gearboxes, and fans—operates under extreme conditions. And while these machines are built to be robust, their reliability often depends on something much smaller: sealing components.

Seals are not just accessories. They are critical to keeping lubricants in, contaminants out, and systems running smoothly. In steel plants, where downtime can cost thousands per hour, choosing the right seal is not optional—it’s essential.

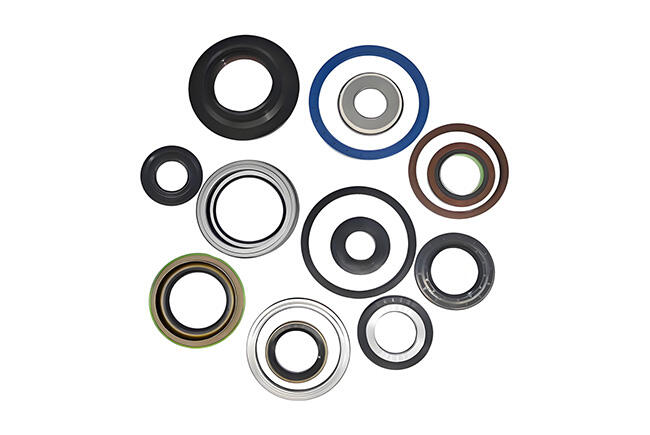

Common Sealing Components in Steel Plants

Rotary Shaft Oil Seals These are used in motors, gearboxes, fans, and mill bearings. In steel plants, oil seals must resist high temperatures, abrasive particles, and continuous rotation. Materials like FKM (fluoroelastomer) and PTFE (polytetrafluoroethylene) are preferred for their heat resistance and low wear. In some cases, metal-reinforced structures are used to improve stability.

O-Rings O-rings are found in hydraulic cylinders, valves, pumps, and pipe joints. NBR (nitrile rubber) is common for general oil resistance, while FKM is used in high-temperature or chemically aggressive environments. Silicone and HNBR (hydrogenated nitrile) are also selected for specific applications.

Hydraulic Seals Steel plants rely heavily on hydraulic systems. U-rings, Glyd rings and step seals are used in cylinders that operate under high pressure and frequent motion. These seals are typically made from polyurethane (PU) or composite elastomers, offering a balance of flexibility and durability.

Key Performance Factors

The performance of seals in steel plants depends on several critical factors:

Temperature Resistance: Ambient temperatures near furnaces and rolling lines often exceed 200°C. Standard rubber compounds degrade quickly under such conditions.

Pressure Endurance: Hydraulic systems typically operate above 20 MPa. Seals must maintain integrity under constant load.

Wear Resistance: High-speed shafts and rollers cause rapid wear. Materials must be selected for long-term durability.

Chemical Compatibility: Acid baths and chemical treatments require seals that resist aggressive media.

Dust Protection: Dense airborne particles make dust exclusion a top priority.

What Distributors and Wholesalers Should Consider

Steel plant customers are not just looking for seals—they’re looking for solutions. Their questions are practical:

“Do you have this size in stock?”

“Can you ship today? Our mill is down.”

“Do you offer seals for high-temperature acid lines?”

“Can you customize a seal for our non-standard hydraulic cylinder?”

For distributors and wholesalers, the ability to respond quickly, offer technical guidance, and support custom requirements is what sets a supplier apart.

How NQKSF Supports the Steel Industry

NQKSF has built its reputation by addressing the real-world needs of industrial clients. For steel plants, the company offers:

Standard Parts, Fast Delivery With over ten thousand specifications covering O-rings, oil seals, and more, NQKSF maintains robust inventory levels to respond quickly to urgent requests.

Customized Full-Service Solutions From material selection and structural design to production and testing, NQKSF provides non-standard seals tailored to specific working conditions.

Technical Empowerment With more than 30 years of industry experience, NQKSF helps clients optimize sealing systems, reduce maintenance costs, and improve equipment reliability.

Company Highlights

NQKSF is recognized as a leader in the sealing industry. The company operates a modern manufacturing facility and exports to over 80 countries. It collaborates with global brands and has earned multiple honors, including:

Provincial Technology Innovation Center

Specialized and Innovative Enterprise

High-Tech Enterprise

Leading company in regional industrial clusters

With a full range of models and strong production capacity, NQKSF is positioned to serve steel manufacturers worldwide.

Sealing components in steel plants are not just technical parts—they are strategic assets. From oil seals and O-rings to hydraulic seals and high-temperature gaskets, each plays a vital role in protecting equipment and ensuring operational continuity. For suppliers, understanding the demands of steel production and offering responsive, technically sound solutions is the key to long-term partnerships.

NQKSF combines manufacturing strength, technical expertise, and global reach to support the sealing needs of steel plants—helping them stay efficient, safe, and productive in one of the world’s toughest industrial environments.

Hot News

Hot News