Have you ever wondered what helps many machines operate smoothly day after day, often under intense pressure and temperature? You might not give it much thought, but the BASL oil seal is doing a lot of the heavy lifting behind the scenes. This small, often overlooked part plays a critical role in keeping machines running efficiently by sealing in lubricants and keeping out dirt, dust, and other harmful particles.

Why BASL Oil Seals Deserve Attention

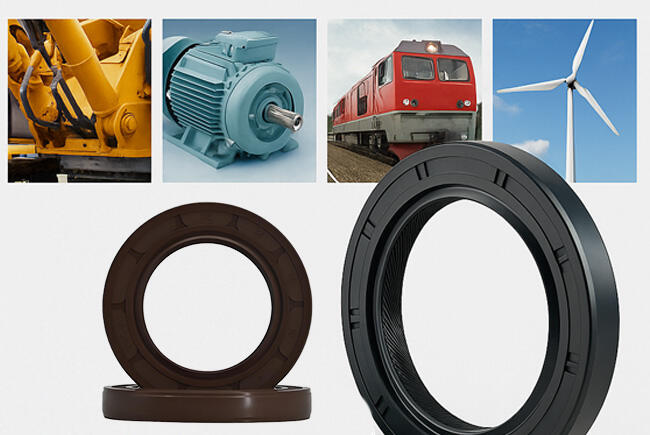

There’s a good reason why many industries rely on BASL oil seals. Unlike basic seals, the BASL version features a double-lip design: one lip keeps the lubricant in, while the second lip acts as a barrier against contaminants like dust and moisture. Together, they offer a smart, practical solution to protect rotating shafts in a wide range of machinery.

At the heart of the design is a reinforced metal frame wrapped in flexible rubber. The sealing lip maintains firm contact with the rotating shaft, while the dust lip prevents outside particles from entering. This dual function makes BASL oil seals especially effective in demanding environments where single-lip designs often fall short — like high-speed, high-temperature, or high-pressure conditions.

Not All BASL Oil Seals (TC Oil Seal) Are the Same — Material Makes a Difference

Different working conditions call for different materials, and BASL oil seals are available in several types to suit various applications. Two of the most commonly used materials are:

Fluororubber (FKM): Known for its excellent resistance to heat and chemicals, FKM is ideal for sealing systems in chemical plants, oil refineries, and high-temperature equipment. It holds up well even under extreme thermal conditions.

Nitrile rubber (NBR): With great oil and abrasion resistance, NBR is widely used in automotive gear systems, hydraulic components, and general industrial machinery. It offers a balance of performance and affordability, making it a popular choice for everyday applications.

Each material brings unique strengths, so selecting the right one depends on your specific working environment — whether it’s dealing with heat, pressure, chemicals, or all of the above.

Standard Sizes or Custom-Made — We’ve Got You Covered

At NQKSF, we understand that not every piece of equipment works with off-the-shelf parts. That’s why, in addition to maintaining a large inventory of standard BASL oil seals (over 10,000 specifications available), we also provide fully customized sealing solutions.

Got aging machinery that needs a hard-to-find size? Working in extreme conditions that require a special material? Our experienced engineers are here to help. From material selection and structural design to testing and final delivery, we’ll make sure your seals are precisely maBASLhed to your system’s requirements — not just in theory, but in practice.

Trusted by Clients in 80+ Countries

With more than 30 years in the sealing industry, NQKSF has earned a reputation as a reliable partner in sealing solutions. Our products are used in industries ranging from automotive and agriculture to energy, mining, and heavy machinery. To date, we’ve shipped to customers in over 80 countries, and our global reach continues to grow.

But we’re not just selling products — we’re providing ongoing technical support and solutions that help reduce long-term maintenance costs. We work closely with our clients to optimize sealing performance, improve equipment stability, and extend service life.

BASL Oil Seals: Small Components, Big Impact

At first glance, a BASL oil seal might seem like a small and simple part. But when it comes to machinery performance, it plays a big role in keeping things running smoothly. With the right material, a well-thought-out design, and proper installation, BASL oil seals can help prevent leaks, reduce wear, and minimize downtime.

At NQKSF, we’re proud to provide not only reliable, high-quality products, but also the custom engineering support that helps our customers solve real-world challenges. Whether you need a standard seal for regular maintenance or a custom solution for a unique application, our team is ready to help you get the job done right.

BASL oil seals are more than just spare parts — they are essential tools for machine longevity and reliability. At NQKSF, we’re committed to providing sealing solutions that meet the demands of modern industry, from conventional machinery to extreme operating conditions. With decades of experience, global service capabilities, and a problem-solving mindset, we’re ready to be your trusted sealing partner — now and in the future.

Hot News

Hot News