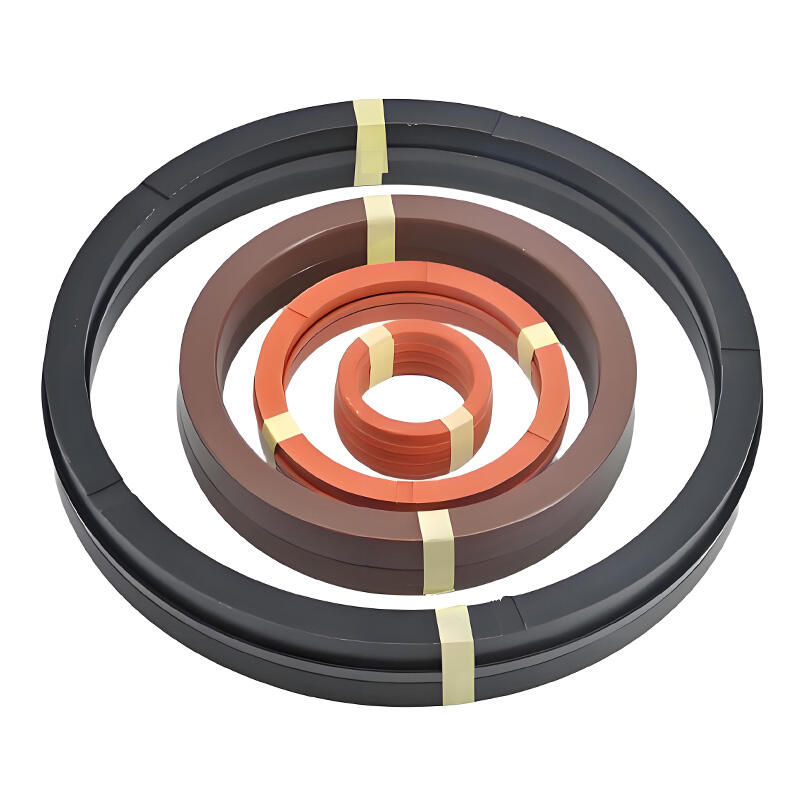

big rubber o rings

Big rubber O rings are essential sealing components widely used in various industrial applications. These circular elastomeric seals are specifically designed to create airtight and liquid-tight barriers between two or more mechanical parts. Manufactured from high-quality rubber compounds, these rings feature larger dimensions compared to standard O rings, making them ideal for heavy-duty applications. The rings are engineered to maintain their structural integrity under extreme pressure, temperature variations, and exposure to different chemicals. Their unique design incorporates precise cross-sectional geometry that ensures optimal compression and recovery characteristics, leading to superior sealing performance. These components are particularly valuable in hydraulic systems, pneumatic equipment, and large-scale industrial machinery where maintaining proper seals is crucial. The versatility of big rubber O rings extends to their compatibility with various mounting configurations and their ability to accommodate different groove designs. Their robust construction allows them to withstand dynamic movements while maintaining consistent sealing pressure, making them indispensable in applications requiring reliable containment of fluids or gases.