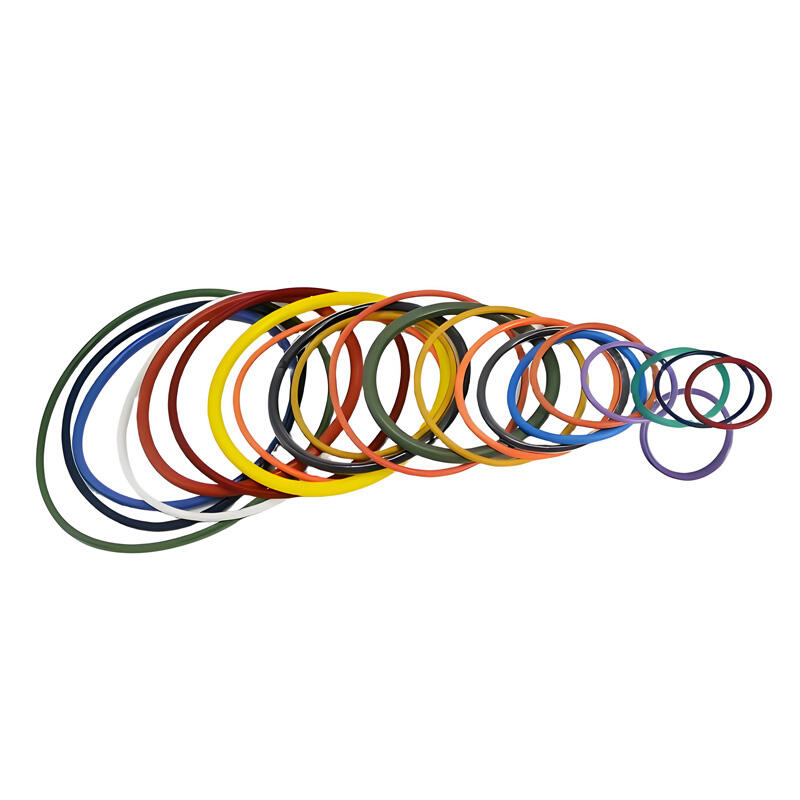

rubber o ring gasket

A rubber O-ring gasket is a critical sealing component designed to prevent leakage between two mating surfaces in mechanical assemblies. These versatile sealing elements feature a donut-shaped cross-section and are manufactured from various elastomeric materials to suit different applications. The primary function of rubber O-ring gaskets is to create an impermeable barrier against liquids and gases when compressed between two surfaces. They operate by filling microscopic surface irregularities and maintaining constant contact pressure, even under varying temperatures and pressures. The technology behind these gaskets involves precise material selection and manufacturing processes to ensure optimal compression set resistance, chemical compatibility, and temperature tolerance. Rubber O-ring gaskets find extensive applications across numerous industries, including automotive, aerospace, plumbing, and industrial machinery. They are particularly valuable in dynamic applications where movement occurs between sealed components, as their elastic properties allow them to maintain an effective seal while accommodating mechanical stress. The design simplicity of O-ring gaskets, combined with their reliability and cost-effectiveness, makes them an ideal choice for both high-pressure systems and general-purpose sealing applications.