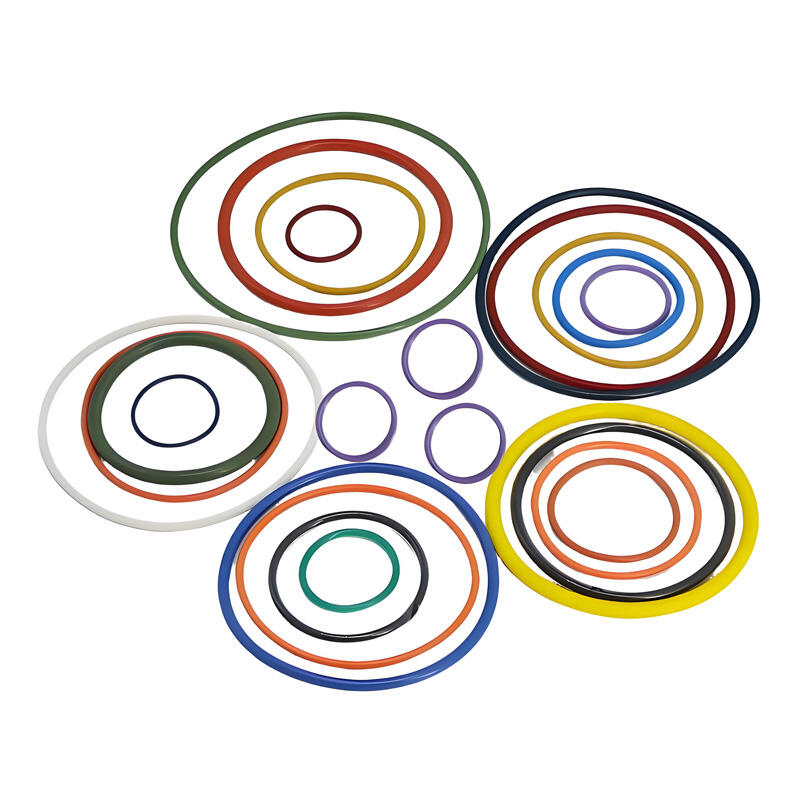

o rubber ring

O rubber rings, also known as O-rings, are essential circular sealing components designed to prevent leakage in mechanical assemblies. These precision-engineered elastomer seals feature a donut-like shape with a round cross-section, providing reliable sealing solutions across various industries. The primary function of an O rubber ring is to create an effective barrier between two surfaces, preventing the passage of liquids, gases, or other substances. When compressed between mating surfaces, the O-ring deforms to fill the gap, creating a tight seal that maintains its integrity under varying pressure conditions. These versatile sealing elements are manufactured using different elastomer materials, including nitrile (NBR), silicone, EPDM, and fluorocarbon (FKM), each suited for specific operating conditions and chemical environments. The design simplicity of O rubber rings, combined with their excellent sealing properties and cost-effectiveness, makes them indispensable in applications ranging from automotive systems and hydraulic equipment to medical devices and aerospace components.