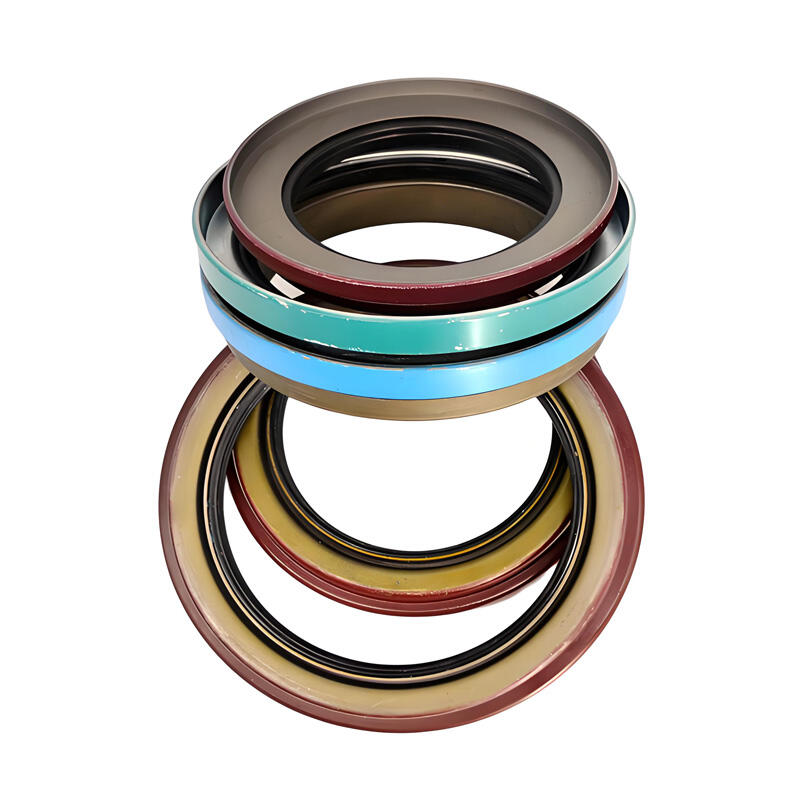

oil seal supplier

An oil seal supplier serves as a crucial partner in industrial manufacturing, providing essential components that prevent fluid leakage and ensure optimal machinery performance. These suppliers specialize in designing, manufacturing, and distributing high-quality oil seals that meet diverse industrial requirements. Modern oil seal suppliers leverage advanced manufacturing technologies and quality control systems to produce seals that withstand extreme temperatures, pressures, and chemical exposure. They typically offer an extensive range of standard and custom solutions, including radial shaft seals, hydraulic seals, and specialized sealing solutions for automotive, aerospace, and heavy machinery applications. Professional suppliers maintain strict quality standards, often holding ISO certifications and implementing rigorous testing protocols to ensure product reliability. They also provide technical support, helping customers select the most appropriate sealing solutions for their specific applications. The best suppliers invest in research and development to continuously improve their products, incorporating innovative materials and designs to enhance seal performance and longevity. They maintain comprehensive inventory systems and efficient distribution networks to ensure prompt delivery and minimize customers' downtime.