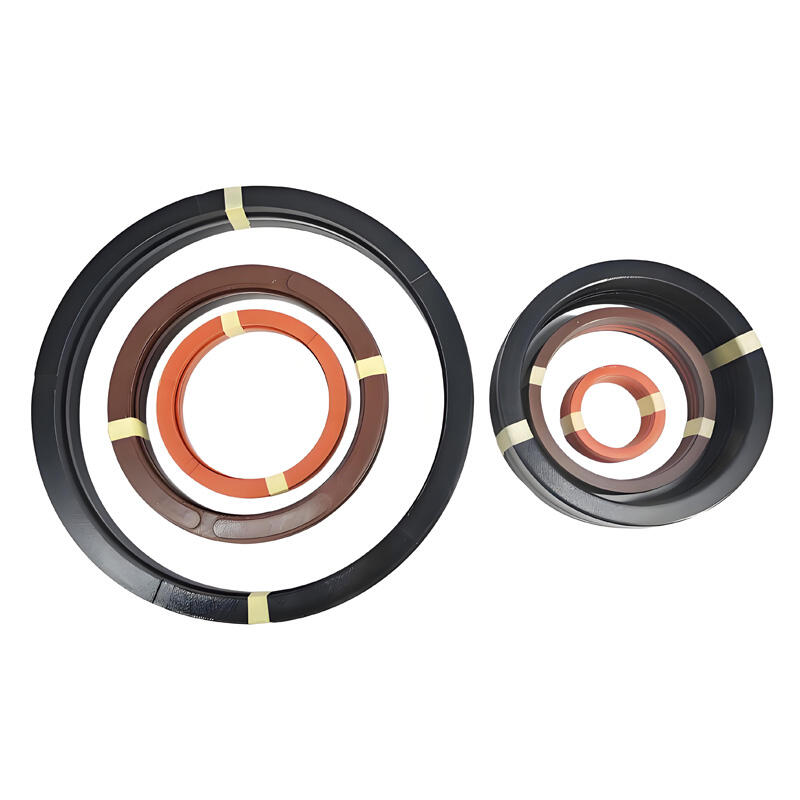

oil seal in motor

An oil seal in motor applications represents a critical component designed to prevent oil leakage and protect against external contaminants in various mechanical systems. These precision-engineered seals consist of elastomeric materials, typically reinforced with metal or other durable compounds, creating an effective barrier between moving parts. The primary function involves maintaining proper lubrication within the motor assembly while ensuring optimal performance and longevity. Modern oil seals incorporate advanced lip design technology, enabling them to withstand high temperatures, pressure variations, and diverse operating conditions. These seals are strategically positioned at crucial points where rotating shafts meet stationary components, effectively containing lubricants within the motor housing. The design typically features a spring-loaded sealing lip that maintains consistent contact pressure against the shaft, ensuring reliable sealing performance even under dynamic conditions. Oil seals play a vital role in industrial motors, automotive engines, power transmission systems, and various mechanical applications where fluid containment is essential. Their implementation significantly reduces maintenance requirements, extends equipment life, and prevents environmental contamination through oil leakage.