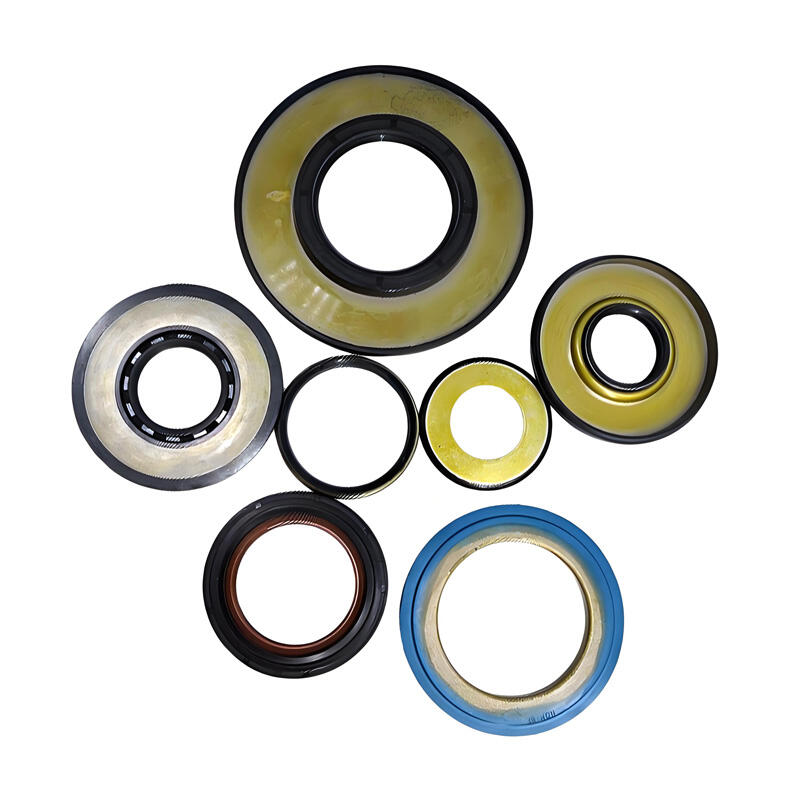

rubber oil seal types

Rubber oil seals are essential components designed to prevent oil leakage and protect mechanical systems from contamination. These seals come in various types, including radial shaft seals, O-rings, and lip seals, each engineered for specific applications. Radial shaft seals excel in rotating machinery, providing reliable sealing for both high and low-speed applications. O-rings offer versatile sealing solutions with their simple yet effective circular design, capable of maintaining integrity under various pressure conditions. Lip seals feature a primary lip that maintains constant contact with the shaft surface, creating an effective barrier against oil leakage while a secondary lip guards against external contaminants. Advanced manufacturing processes ensure these seals maintain their performance across diverse operating temperatures, pressures, and chemical environments. The materials used in modern rubber oil seals, such as nitrile (NBR), fluorocarbon (FKM), and silicone, are carefully selected to provide optimal resistance to oils, chemicals, and temperature extremes. These seals play a critical role in automotive engines, industrial machinery, hydraulic systems, and power transmission equipment, where their reliability directly impacts system efficiency and maintenance intervals.