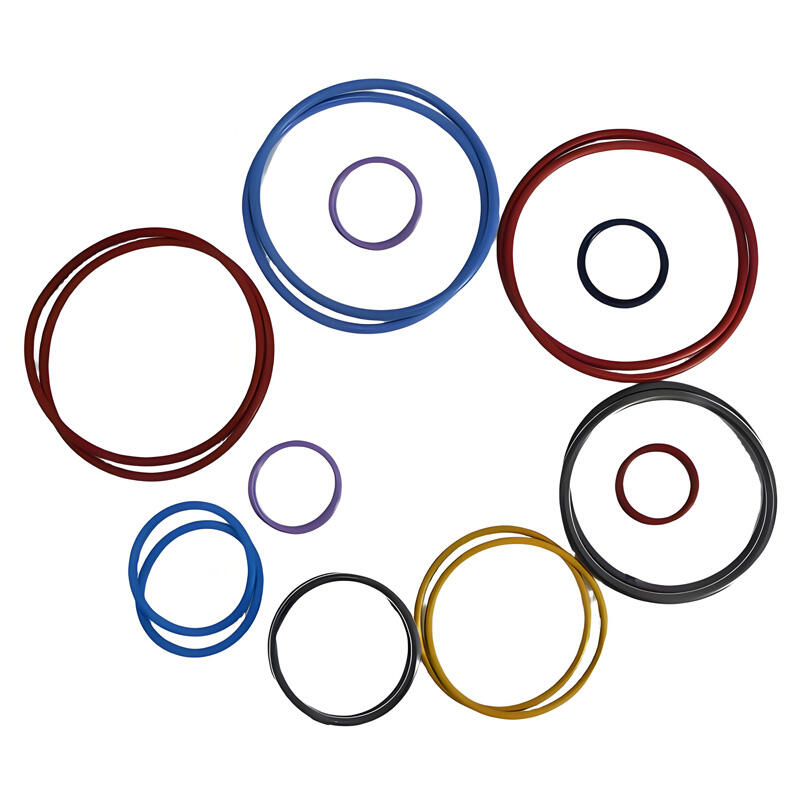

seal ring price

Seal ring prices reflect the complex engineering and quality materials required for these essential industrial components. These precision-engineered components play a crucial role in maintaining system integrity across various applications, from automotive to aerospace industries. The pricing structure typically considers factors such as material composition, size specifications, durability requirements, and manufacturing precision. High-performance seal rings, often crafted from materials like stainless steel, bronze, or advanced polymers, command premium prices due to their enhanced resistance to pressure, temperature, and chemical exposure. The cost also varies based on customization needs, with standard sizes generally being more economical than custom-designed solutions. Modern manufacturing processes, including CNC machining and advanced molding techniques, contribute to the overall pricing structure while ensuring consistent quality and reliability. The market offers various price points to accommodate different application requirements, from basic industrial sealing solutions to highly specialized aerospace-grade components. Manufacturers often provide volume-based pricing tiers, making bulk purchases more cost-effective for large-scale industrial applications.