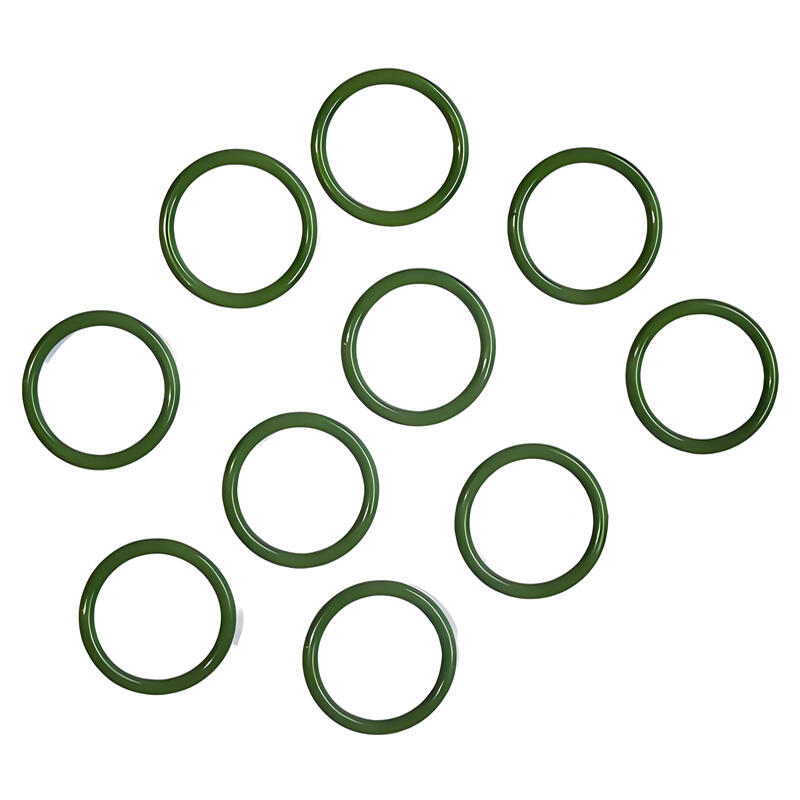

bonded seal

A bonded seal represents a sophisticated sealing solution that combines a metal washer with an elastomeric compound, creating a highly effective sealing element. This innovative design consists of a metallic ring with a rubber or synthetic material bonded to its inner diameter, offering superior sealing capabilities in various industrial applications. The metal component provides structural integrity and prevents over-compression, while the elastomeric material ensures a tight seal against both internal and external pressures. These seals are engineered to maintain their effectiveness across a wide range of temperatures and pressures, making them ideal for hydraulic systems, pneumatic applications, and fluid power equipment. The unique construction allows for excellent resistance to extrusion and provides reliable sealing even under dynamic conditions. Bonded seals are particularly valued in industries where leak prevention is critical, such as automotive, aerospace, and heavy machinery manufacturing. Their design accommodates both static and dynamic applications, offering consistent performance in environments where traditional sealing solutions might fail. The integration of metal and elastomer creates a seal that combines the best properties of both materials, resulting in enhanced durability and reliable sealing performance.