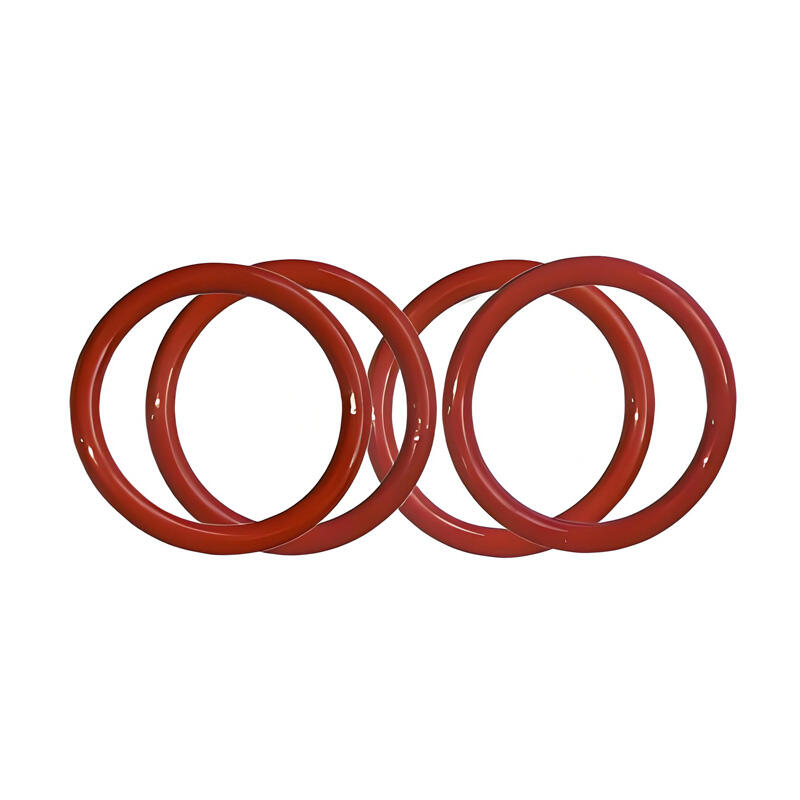

seal rings for sale

Seal rings represent a crucial component in various industrial and mechanical applications, offering reliable sealing solutions for diverse equipment and machinery. These precision-engineered components are designed to prevent leakage of fluids, gases, and other substances while maintaining optimal pressure within systems. Manufactured using high-grade materials such as stainless steel, bronze, or advanced polymers, seal rings ensure long-lasting performance under challenging operating conditions. The rings feature precise dimensions and surface finishes that guarantee perfect sealing between mating surfaces, effectively preventing media loss and contamination. Modern seal rings incorporate innovative design elements that enhance their durability and reliability, including specially engineered profiles that optimize contact pressure and minimize wear. These components are essential in hydraulic systems, pneumatic equipment, automotive applications, and various industrial machinery where maintaining system integrity is paramount. The versatility of seal rings extends to their ability to function effectively across a wide range of temperatures, pressures, and chemical environments, making them indispensable in critical applications where seal failure is not an option.