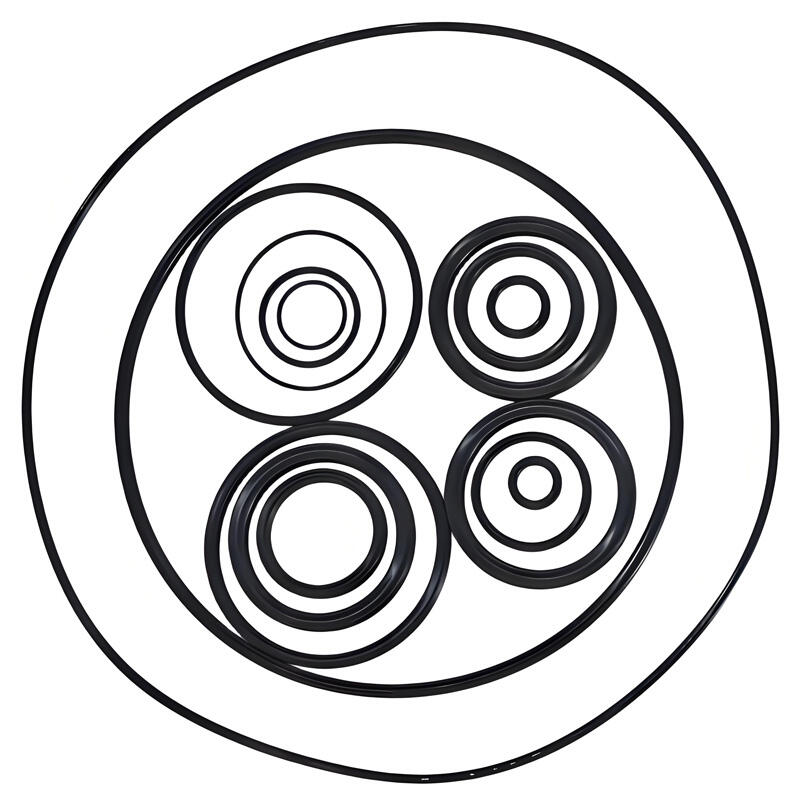

thick rubber o rings

Thick rubber O rings are essential sealing components engineered for demanding industrial applications where standard O rings may fall short. These precision-manufactured seals feature increased cross-sectional thickness, providing enhanced compression resistance and superior sealing capabilities. Crafted from high-grade elastomeric materials, thick rubber O rings offer exceptional durability and reliability in challenging environments. These components excel in applications requiring robust sealing solutions, particularly in heavy machinery, hydraulic systems, and high-pressure equipment. The increased thickness of these O rings provides additional material for compression, resulting in improved sealing performance and extended service life. They are specifically designed to maintain their structural integrity under extreme conditions, including high pressure, temperature fluctuations, and chemical exposure. The versatility of thick rubber O rings makes them ideal for both static and dynamic sealing applications, while their robust construction ensures consistent performance in critical systems. These seals are available in various materials, including NBR, EPDM, and Viton, allowing for optimal material selection based on specific application requirements.