Understanding the Versatility of Industrial R23 Sealing Solutions

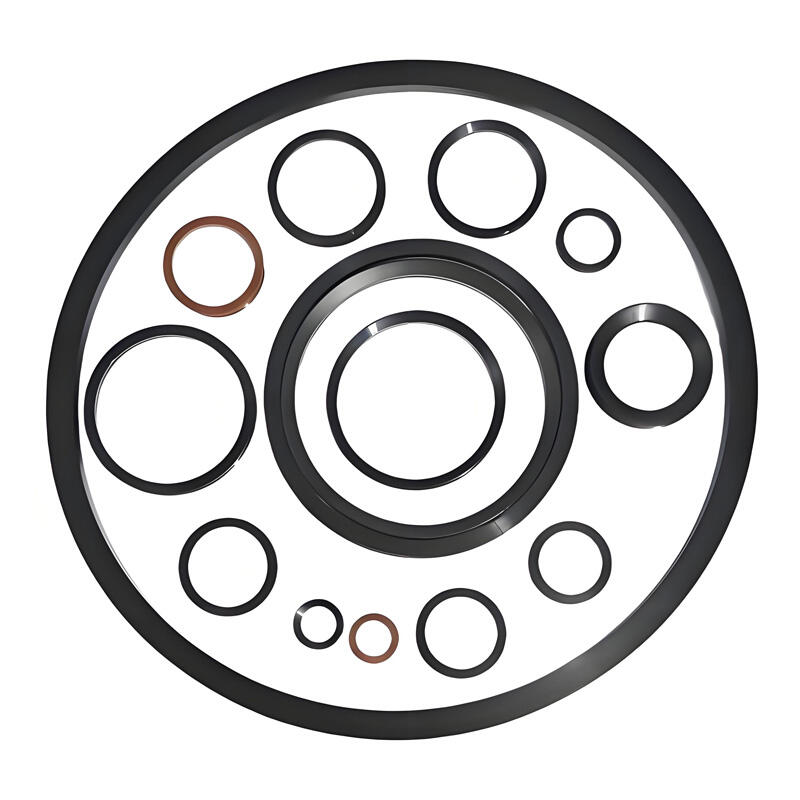

In the demanding world of industrial applications, the R23 seal has emerged as a crucial component that delivers exceptional performance across diverse operating conditions. These high-quality sealing solutions combine advanced materials with precision engineering to ensure reliable containment and protection in critical systems. The growing adoption of R23 seals across various industries demonstrates their vital role in maintaining operational efficiency and system integrity.

Modern manufacturing processes rely heavily on dependable sealing mechanisms, and the R23 seal stands out for its remarkable adaptability and durability. From extreme temperature environments to high-pressure applications, these seals have proven their worth in countless industrial scenarios, making them an indispensable element in contemporary engineering solutions.

Industrial Manufacturing Applications

Heavy Equipment and Machinery

The manufacturing sector represents one of the largest markets for R23 seal applications. In heavy machinery, these seals play a critical role in protecting bearings, shafts, and other vital components from contamination and lubricant loss. The robust design of the R23 seal ensures consistent performance even under severe operating conditions, including exposure to abrasive particles and varying pressure levels.

Manufacturing equipment such as CNC machines, industrial presses, and automated assembly lines extensively utilize R23 seals to maintain precision and prevent system failures. The seal's ability to withstand continuous operation while maintaining its integrity makes it particularly valuable in high-volume production environments.

Process Equipment and Systems

Chemical processing plants and refineries rely on R23 seals for their critical equipment and piping systems. These seals excel in containing aggressive media and maintaining system pressure integrity. Their chemical resistance properties make them ideal for applications involving corrosive substances and high-temperature processes.

The food and beverage industry also benefits from R23 seals in their processing equipment, where maintaining hygiene and preventing contamination is paramount. The seals comply with industry standards and regulations while ensuring reliable operation in both wet and dry processing environments.

Transportation and Automotive Sector

Vehicle Powertrain Systems

In automotive applications, R23 seals are essential components in powertrain systems, where they protect critical moving parts from oil leakage and external contaminants. These seals maintain their effectiveness despite constant exposure to high temperatures and mechanical stress, contributing to extended vehicle service life and reduced maintenance requirements.

The growing electric vehicle market has created new applications for R23 seals, particularly in battery cooling systems and electric motor assemblies. Their excellent temperature resistance and durability make them ideal for these innovative automotive applications.

Heavy Transport Equipment

Commercial vehicles and heavy transport equipment extensively employ R23 seals in their hydraulic systems and power transmission components. These applications demand seals that can withstand extreme pressures and continuous operation while maintaining their sealing properties over extended periods.

Railway systems and marine equipment also rely on R23 seals for various critical applications, from wheel bearing assemblies to propulsion system components. The seal's proven reliability in these demanding environments has made it a preferred choice for transport equipment manufacturers.

Energy Sector Applications

Power Generation Equipment

The energy sector employs R23 seals in various power generation equipment, from traditional thermal power plants to renewable energy systems. These seals are crucial in turbine systems, where they must maintain integrity under high temperatures and rotational speeds. Their application in cooling systems and fluid handling equipment is equally important for maintaining efficient power generation operations.

Wind turbines represent a growing application area for R23 seals, particularly in gearbox and bearing assemblies. The seals' ability to perform reliably in remote installations with minimal maintenance has made them invaluable in the renewable energy sector.

Oil and Gas Equipment

In the oil and gas industry, R23 seals are essential components in drilling equipment, pumping systems, and processing facilities. These applications often involve extreme pressures and temperatures, along with exposure to aggressive fluids and gases. The seal's robust design and material properties ensure reliable performance in these challenging environments.

Subsea equipment particularly benefits from R23 seals' exceptional pressure resistance and long-term reliability. These seals help maintain system integrity in deep-water operations where maintenance access is limited and failure costs are extremely high.

Aerospace and Defense Applications

Aircraft Systems

The aerospace industry relies on R23 seals for various critical applications in aircraft systems. From engine components to landing gear assemblies, these seals must maintain their integrity under extreme temperature variations and pressure changes. Their application in fuel systems and hydraulic equipment is crucial for ensuring flight safety and reliability.

Modern aircraft designs increasingly incorporate R23 seals in their advanced systems, including environmental control units and actuator assemblies. The seal's proven track record in aerospace applications has made it a trusted component in both commercial and military aircraft.

Space and Defense Equipment

Space vehicles and satellite systems utilize R23 seals in various critical applications where failure is not an option. These seals must perform reliably in the vacuum of space while withstanding extreme temperature cycles and radiation exposure. Their use in propulsion systems and life support equipment demonstrates their importance in space exploration.

Defense applications include military vehicles, weapons systems, and specialized equipment where R23 seals provide crucial protection against harsh environmental conditions and ensure operational readiness.

Frequently Asked Questions

What makes R23 seals suitable for high-temperature applications?

R23 seals are engineered with advanced materials that maintain their mechanical properties and sealing effectiveness at elevated temperatures. Their unique compound formulation provides excellent thermal stability and resistance to degradation, making them ideal for applications where traditional seals might fail.

How long can R23 seals typically last in industrial applications?

The service life of R23 seals varies depending on operating conditions, but they generally provide reliable performance for several years in properly maintained systems. Regular monitoring and adherence to installation specifications can significantly extend their operational lifespan.

Can R23 seals be custom-designed for specific applications?

Yes, R23 seals can be customized to meet specific application requirements. Manufacturers can modify dimensions, materials, and design features to optimize performance for particular operating conditions, pressure requirements, and environmental factors.

What maintenance practices are recommended for R23 seals?

Proper maintenance of R23 seals includes regular inspection for wear, correct alignment during installation, and maintaining appropriate lubrication where required. Following manufacturer guidelines for handling and installation is crucial for optimal performance and longevity.