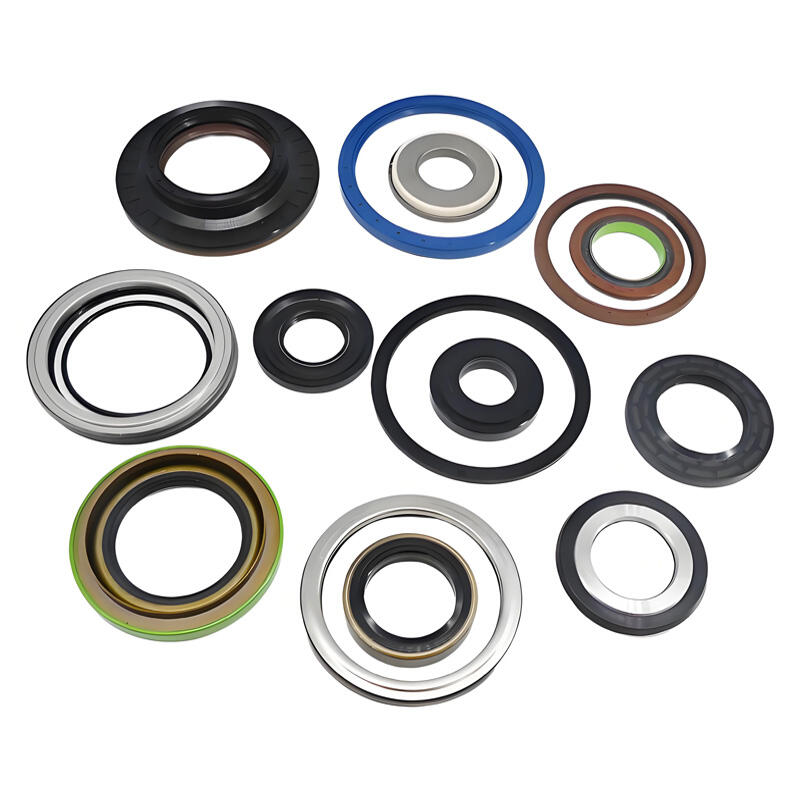

Structure and Classification of Modern Oil Seal Systems In industrial equipment, automotive assemblies, and precision machinery, the oil seal plays a foundational role in ensuring stable operation. While it is often treated as a standard component, t...

VIEW MORE

Understanding the Role of Oil Seal Quality in Industrial Systems Oil Seal is a critical component in modern mechanical and industrial systems. Whether used in automotive drivetrains, industrial gearboxes, hydraulic equipment, or heavy-duty machinery,...

VIEW MORE

Precision Sealing and the Role of a Reliable Oil Seal Manufacturer In modern industrial systems, stable sealing performance is a basic requirement rather than an added advantage. From rotating shafts in automotive powertrains to high-speed equipment ...

VIEW MORE

Understanding Oil Seal Quality and Market Evaluation In industrial transmission systems, fluid control assemblies, and rotating machinery, the oil seal plays a fundamental role in maintaining performance stability and operational safety. An oil seal ...

VIEW MORE

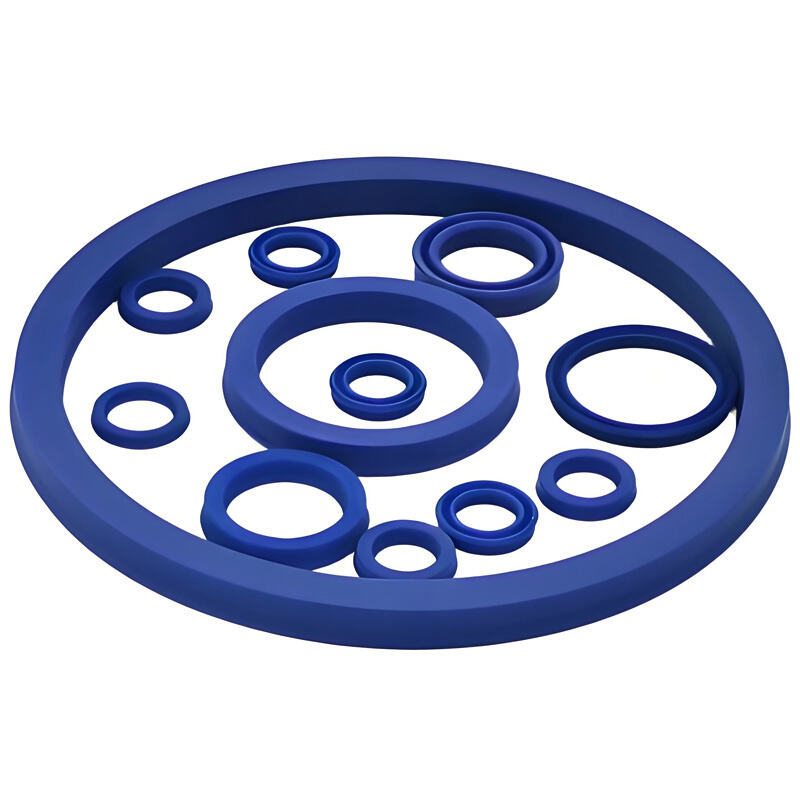

Industrial applications demand reliable sealing solutions that can withstand extreme conditions, chemical exposure, and mechanical stress. An O-Ring Kit serves as a comprehensive solution for maintenance teams, engineers, and technicians who need imm...

VIEW MORE

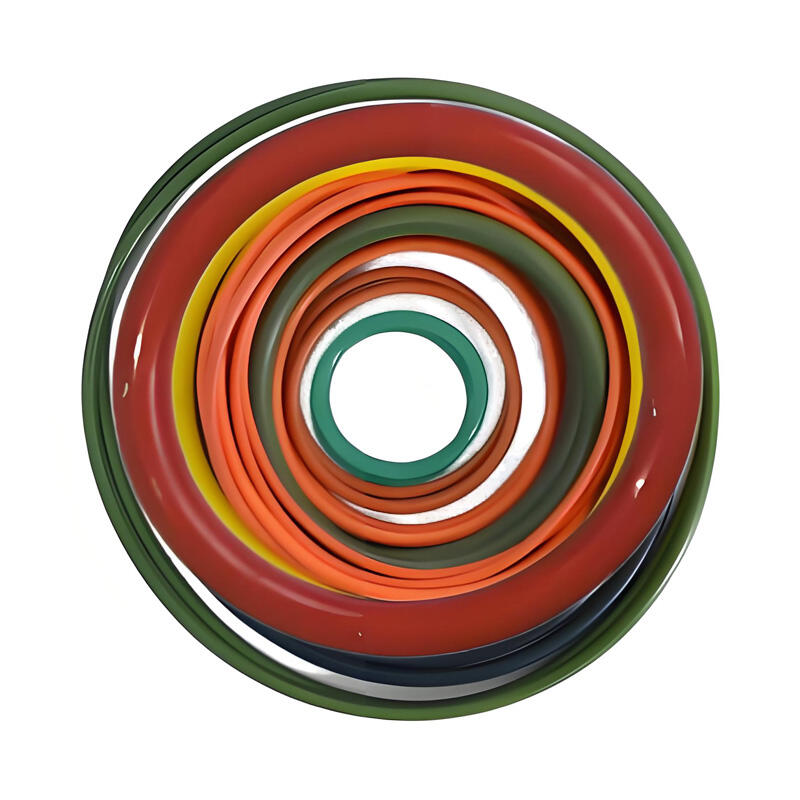

Industrial sealing applications demand precise attention to ring specification details that directly impact operational efficiency and system reliability. Understanding the critical parameters that define effective sealing performance helps engineers...

VIEW MORE

Industrial machinery operates under extreme conditions where precision engineering and component reliability determine operational success. Among the critical components that ensure seamless functionality, the oil seal stands as a fundamental element...

VIEW MORE

When selecting a double lip shaft oil seal for industrial applications, buyers must evaluate numerous critical factors that directly impact equipment performance and longevity. These specialized rubber oil seal components serve as the primary barrier...

VIEW MORE

Heavy-duty machinery operates under extreme conditions that demand reliable sealing solutions to prevent fluid leakage and contamination. The selection of appropriate rubber oil seal materials plays a critical role in maintaining equipment performanc...

VIEW MORE

Modern automotive systems operate under extreme conditions, requiring precise engineering solutions to maintain optimal performance and longevity. Among the most critical components ensuring system reliability are shaft oil seals, which serve as the ...

VIEW MORE

Industrial machinery operates under demanding conditions where contamination, fluid leakage, and component wear can lead to costly downtime and equipment failure. Shaft oil seals represent one of the most critical components in maintaining machinery ...

VIEW MORE

Industrial machinery relies heavily on effective sealing solutions to prevent contamination, maintain lubrication, and ensure optimal performance. Among the most critical components in rotating equipment, the rotary shaft seal stands as a fundamental...

VIEW MORE