Industrial machinery operates under extreme conditions where precision engineering and component reliability determine operational success. Among the critical components that ensure seamless functionality, the oil seal stands as a fundamental element protecting rotating shafts from contamination and fluid leakage. These seemingly simple components bear the responsibility of maintaining system integrity across countless applications, from automotive transmissions to heavy industrial equipment. Understanding the crucial role of oil seal technology reveals why industrial systems worldwide depend on these essential sealing solutions for optimal performance and longevity.

Understanding Rotary Oil Seal Fundamentals

Basic Design and Construction Principles

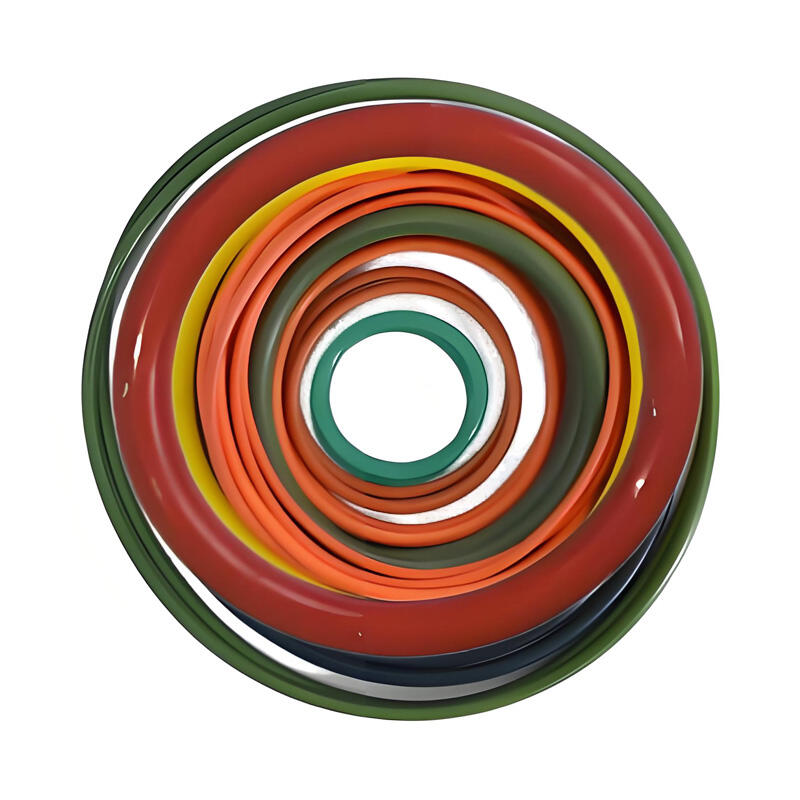

The rotary oil seal represents a sophisticated engineering solution designed to create a dynamic barrier between rotating and stationary components. These seals typically consist of a flexible elastomeric sealing lip, a metal case for structural support, and often a garter spring that maintains consistent contact pressure against the shaft surface. The sealing lip material selection depends on operating conditions, with nitrile rubber, fluorocarbon, and polytetrafluoroethylene being common choices for different temperature and chemical compatibility requirements.

Manufacturing precision plays a crucial role in oil seal effectiveness, as dimensional tolerances directly impact sealing performance. The sealing lip geometry requires careful engineering to balance sealing efficiency with friction generation, ensuring optimal contact pressure distribution across the shaft interface. Advanced manufacturing techniques utilize computer-controlled molding processes to achieve consistent wall thickness and precise lip contours that maintain sealing integrity throughout the component's operational life.

Material Science and Performance Characteristics

Modern oil seal materials undergo extensive testing to validate performance under various operating conditions. Elastomer compounds must demonstrate resistance to temperature extremes, chemical exposure, and mechanical wear while maintaining flexibility and sealing effectiveness. The development of specialized compounds has expanded the operational envelope of oil seal applications, enabling reliable performance in environments previously considered unsuitable for elastomeric sealing solutions.

Surface treatments and coatings enhance oil seal durability by reducing friction and improving wear resistance. Advanced surface engineering techniques, including plasma treatments and specialized lubricant coatings, extend service life while maintaining sealing performance. These innovations address the increasing demands of modern industrial applications where extended maintenance intervals and improved reliability are essential operational requirements.

Critical Functions in Industrial Applications

Contamination Prevention and System Protection

Industrial environments expose machinery to various contaminants that can compromise internal components and fluid systems. The oil seal serves as the primary defense against ingress of dust, dirt, moisture, and other environmental contaminants that would otherwise cause premature wear and system failure. This protective function becomes particularly critical in applications such as mining equipment, construction machinery, and marine systems where harsh operating conditions are standard.

Effective contamination exclusion extends beyond simple particle filtration to include protection against chemical exposure and corrosive substances. Industrial oil seal designs incorporate features such as excluder lips and protective shields that create multiple barriers against contaminant ingress. These multi-stage protection systems ensure that internal lubricants remain clean and functional throughout extended operational periods, reducing maintenance requirements and improving system reliability.

Fluid Retention and System Efficiency

Maintaining proper fluid levels within rotating machinery requires reliable sealing performance that prevents lubricant leakage while allowing normal thermal expansion and contraction. The oil seal design must accommodate shaft movement, thermal cycling, and pressure variations without compromising sealing integrity. Advanced sealing technologies incorporate adaptive features that automatically adjust to changing operating conditions while maintaining consistent performance.

System efficiency depends on maintaining optimal lubricant properties and quantities, making oil seal reliability essential for operational success. Fluid loss not only increases operating costs but can lead to inadequate lubrication and catastrophic component failure. Modern industrial applications demand sealing solutions that provide extended service intervals while maintaining leak-free performance under varying load and speed conditions.

Performance Requirements in Harsh Environments

Temperature Extremes and Thermal Management

Industrial applications often subject oil seal components to extreme temperature variations that challenge material properties and dimensional stability. High-temperature environments, such as those found in steel mills and chemical processing plants, require specialized elastomer compounds that maintain sealing effectiveness while resisting thermal degradation. Low-temperature applications, including refrigeration systems and arctic operations, demand materials that remain flexible and maintain sealing contact under cold conditions.

Thermal cycling introduces additional stress factors that oil seal designs must accommodate without failure. Repeated expansion and contraction cycles can cause material fatigue and dimensional changes that compromise sealing performance. Advanced oil seal engineering incorporates thermal compensation features and material formulations that minimize the effects of temperature variations while maintaining reliable sealing throughout extended operational periods.

Chemical Compatibility and Resistance

Modern industrial processes utilize diverse chemical substances that can interact with elastomeric sealing materials, potentially causing swelling, hardening, or chemical breakdown. Oil seal material selection requires comprehensive understanding of chemical compatibility to ensure long-term performance in specific applications. Industries such as petrochemical processing, pharmaceutical manufacturing, and food production demand sealing solutions that resist aggressive chemicals while maintaining food-grade or pharmaceutical-grade compliance.

Chemical resistance testing validates oil seal performance under controlled exposure conditions, providing data essential for proper material selection. Advanced polymer chemistry has developed specialized compounds that offer broad chemical resistance while maintaining mechanical properties necessary for effective sealing. These developments enable reliable oil seal performance in applications previously requiring frequent replacement or alternative sealing technologies.

Installation and Maintenance Considerations

Proper Installation Techniques

Correct oil seal installation procedures are critical for achieving optimal performance and service life. Improper installation can damage sealing surfaces, create stress concentrations, or introduce contaminants that compromise sealing effectiveness. Professional installation requires specialized tools and techniques that protect the oil seal during insertion while ensuring proper alignment and seating within the housing bore.

Installation environments must maintain cleanliness standards that prevent contamination during the assembly process. Dust, debris, or machining residue can create leak paths or accelerate wear once the system begins operation. Quality installation procedures include surface preparation, dimensional verification, and post-installation inspection to confirm proper oil seal positioning and initial sealing performance.

Maintenance Strategies and Lifecycle Management

Effective oil seal maintenance programs incorporate regular inspection schedules and condition monitoring techniques that identify potential issues before system failure occurs. Visual inspection methods can detect early signs of wear, contamination, or improper sealing that indicate the need for preventive maintenance. Advanced monitoring systems utilize vibration analysis, temperature measurement, and fluid analysis to assess oil seal condition and predict remaining service life.

Planned replacement strategies based on operating hours, environmental exposure, and performance history optimize maintenance efficiency while minimizing unplanned downtime. Historical data analysis helps establish realistic service intervals and identify factors that influence oil seal longevity in specific applications. This proactive approach reduces maintenance costs while improving system reliability and operational efficiency.

Technological Advances and Future Developments

Smart Sealing Technologies

Emerging technologies integrate sensors and monitoring capabilities directly into oil seal designs, creating intelligent sealing systems that provide real-time performance feedback. These smart oil seal solutions can detect temperature changes, pressure variations, and wear progression while transmitting data to centralized monitoring systems. This technology enables predictive maintenance strategies and provides early warning of potential seal failure before system damage occurs.

Wireless communication capabilities allow remote monitoring of oil seal performance in applications where direct access is difficult or dangerous. Industrial Internet of Things integration enables comprehensive data collection and analysis that improves understanding of seal behavior under various operating conditions. This information supports optimization of seal design and material selection for enhanced performance and reliability.

Advanced Materials and Manufacturing Processes

Nanotechnology applications in oil seal development create materials with enhanced properties including improved wear resistance, reduced friction, and extended temperature ranges. Nanocomposite materials incorporate microscopic reinforcing particles that strengthen the elastomer matrix while maintaining flexibility and sealing effectiveness. These advanced materials enable oil seal performance in applications previously considered beyond the capabilities of conventional sealing technologies.

Additive manufacturing techniques offer new possibilities for customized oil seal production and rapid prototyping of specialized designs. Three-dimensional printing technologies can create complex geometries and integrate multiple materials within a single component, opening opportunities for innovative sealing solutions. These manufacturing advances support development of application-specific oil seal designs optimized for unique operating conditions and performance requirements.

FAQ

How long do industrial oil seals typically last in service

Industrial oil seal service life varies significantly depending on operating conditions, material selection, and maintenance practices. Under normal conditions, quality oil seals can provide reliable service for several years or thousands of operating hours. However, extreme temperatures, aggressive chemicals, or poor maintenance can reduce service life to months or even weeks. Proper material selection and installation techniques maximize oil seal longevity while regular monitoring helps identify replacement needs before system failure occurs.

What factors should be considered when selecting oil seals for specific applications

Oil seal selection requires careful consideration of operating temperature range, chemical exposure, shaft speed, pressure conditions, and environmental factors. Material compatibility with system fluids and potential contaminants is crucial for long-term performance. Dimensional accuracy, including shaft diameter, housing bore size, and installation depth, ensures proper fit and sealing effectiveness. Application-specific requirements such as food-grade compliance or explosion-proof certification may dictate specialized oil seal designs and materials.

Can damaged oil seals cause significant system problems

Failed oil seals can cause extensive system damage through lubricant loss, contamination ingress, and component wear. Fluid leakage reduces lubrication effectiveness and can lead to bearing failure, gear damage, or complete system breakdown. Contaminant ingress accelerates wear and can cause corrosion or chemical damage to internal components. Environmental contamination from leaked fluids may create safety hazards or regulatory compliance issues, making reliable oil seal performance essential for operational safety and efficiency.

Are there specific installation requirements for different types of oil seals

Different oil seal designs require specific installation procedures to ensure optimal performance and prevent damage during assembly. Spring-loaded seals need careful handling to avoid spring displacement, while interference-fit seals require proper pressing techniques and alignment tools. Surface preparation, including cleaning and inspection of mating surfaces, is critical for all oil seal types. Installation torque specifications, temperature requirements, and post-installation inspection procedures vary by seal design and application requirements.