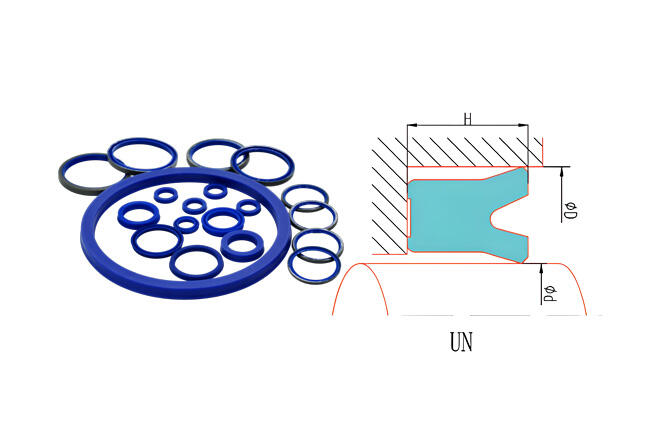

If you’ve worked with hydraulic systems for any length of time, you’ll know that seals are one of those things that seem small—but when they fail, they cause big problems. Especially in equipment like pumps, cylinders, and industrial machines, having a seal you can trust makes all the difference. That’s where UN piston seals come in. At NQKSF, we’ve seen how PU and FKM material UN type seals hold up in the real world.

Why Go with PU and FKM material?

Let’s be honest, not all materials are built for harsh environments. Traditional rubber can crack, swell, or degrade pretty quickly when exposed to aggressive fluids. PU, short for polyurethane, has been gaining traction over the past few years for good reason. It’s sometimes called the “fifth plastic” in the industry—not because it’s trendy, but because it actually performs.

PU combines the flexibility of rubber with the toughness of plastic. That means it’s tough on wear, holds its shape better over time, and resists a wide range of chemicals, including acids, bases, and some solvents. In places where other materials give up, PU just keeps going.

FKM has a high degree of chemical stability and is resistant to high temperatures, oils, high vacuum, acids, alkalis, and a variety of chemicals. It is also one of the elastomers with the best media resistance.

NQKSF is UN piston seal series is designed for hydraulic use, capable of handling temperatures between -20℃ and 250℃. One of the key features is how the seal reacts to pressure—the higher the hydraulic pressure, the tighter the seal becomes. That self-reinforcing behavior is crucial in minimizing oil leakage and maximizing system efficiency.

Real-World Applications

We've seen UN type piston seals used across a wide spectrum of industries. In heavy-duty machinery, especially pumps and hydraulic cylinders, the need for reliable sealing is non-negotiable. If you're in agriculture, construction, or manufacturing, chances are you're already using PU seals somewhere.

UN seals are also commonly used in transmissions, motors, and even robotic arms—where precise movement and pressure control are essential. In areas like water treatment, wind power, and chemical processing, PU seals provide the durability and chemical resistance needed to keep operations stable over the long term.

What’s been clear in our field experience is that the combination of wear resistance and dimensional stability really sets PU and FKM material UN type seals apart. It doesn't matter if it’s running hot or cold, wet or dry—the performance is consistent.

What Makes NQKSF Different?

We’re not just another supplier. NQKSF has over 30 years of experience in sealing solutions. That means we’ve seen every kind of sealing failure, and we know how to prevent it. Our production is backed by a fully equipped manufacturing facility, and we stock tens of thousands of standard parts—O-rings, oil seals, and more—ready to ship on short notice.

For more complex needs, we don’t just push off-the-shelf products. We offer full customization: from material selection and seal design to testing and final delivery. That’s especially important for customers whose systems don’t fit a typical mold.

Our technical team gets hands-on with your application—helping you reduce maintenance time, cut down on system failures, and boost your equipment uptime. It’s not just about seals—it’s about reliability across the board.

Final Thoughts

UN piston seals may not be the flashiest part of your system, but they do a lot of heavy lifting. When designed right—and made with quality materials like NQKSF uses—they can add years of life to your machines. If you’ve been relying on rubber seals and dealing with premature failures, it might be time to make the switch.

At NQKSF, we’re proud to support clients in over 80 countries with reliable sealing solutions that perform where it matters most. If you're looking for a smarter, longer-lasting sealing approach, our PU and FKM material UN type seals series is worth a closer look.

Hot News

Hot News