I've walked around dozens of hydraulic press stations, mining rigs, and industrial cylinders—and honestly, most failures I've seen weren’t due to big parts breaking. Instead, small V‑Packing Sets often gave up first. And that's when clients come to us at NQKSF, looking for a seal stack that doesn’t quit.

We don’t start sales pitches with fancy features—we listen first. Engineers typically describe funny symptoms: slow cylinder return, damp pressure loss, or rings slipping under load. Usually, you can trace it back to the seal stack’s material, lip profile, or just plain wear.

What Is a V‑Packing Set, Really?

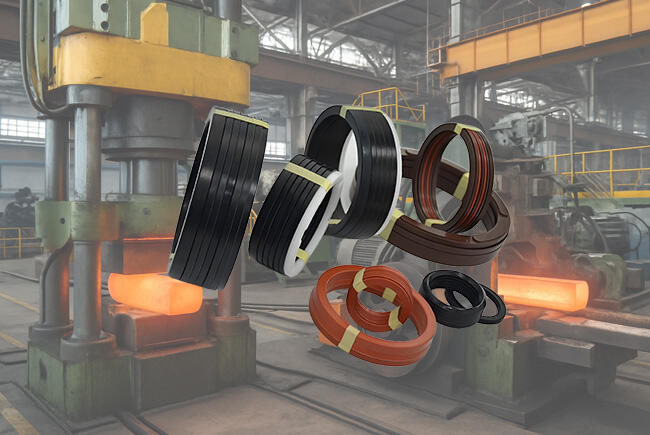

It’s basic: a male ring, a handful of V-rings, and a female ring. Under pressure (often up to 40 MPa), the female ring pushes down, the V-rings spring outward, grip the rod or bore, and you get staged sealing effect. Pressure bleeds gradually through each ring—first one takes most tension, second a bit less, etc. That’s how it really works.

We always listen: what’s your stroke? Load? Fluid temperature? That determines whether you've got NBR, FKM, canvas‑reinforced rubber. At NQKSF, we tailor material stack to real site conditions.

Real Cases We’ve Handled

One site involved metallurgy press cylinders—they were replacing seal stacks every month. Switched to our canvas‑reinforced NBR stack, optimized lip thickness and number of rings. Leak frequency dropped, performance stabilized. client said “looks like a small thing—but saved us downtime, and mechanical tweaking.”

Why Choose V‑Packing Sets from NQKSF?

· We stock thousands of standard sizes—NQKSF platform lets you order same-day.

· Non‑standard cylinder? No problem—we’ll design stack height and ring material based on your specs.

· Our engineers have real experience. We don’t just quote specs; we ask about working cycles, media, temperature, even local part surface finish.

We’re not an OEM broker—we’re a certified high-tech enterprise, provincial innovation center, specialized SME—and all our gear is made in-house.

Applications Where V‑Packing Sets

· High-pressure hydraulic cylinders in metallurgy or heavy machinery

· Mining hydraulics—booms, excavation, down-hole tools

· Fracturing pumps in energy sector (rod-type spheres)

· Industrial presses, forming machines

· Legacy systems where redesigning cylinders isn’t feasible

Made a lot of progress in these areas—because V-packing is forgiving, count‑adjustable, and deals with misalignment better than some more rigid seals.

I’m not saying V-packing is glamorous. It’s not. But in systems where pressure, stroke, and repeat motion matter—a properly matched V-Packing Set is the most dependable fix.

If your system is older, harder to upgrade, and modern seals haven’t performed—just drop me a message. We'll walk through your specs, cylinder bore, rod size, fluid type, cycles per minute… and tailor a V-Packing Set that really works.

That’s the NQKSF difference: practical, tested, and built to last—not on paper, but in your system.

Hot News

Hot News