A lot of people underestimate how much trouble a small leak can cause—until it starts affecting a whole system. If you’ve ever dealt with hydraulic leaks in a gearbox or seen oil dust caking around a drive axle, you’ll understand just how crucial a solid sealing setup really is. Over the years, one solution that’s gained popularity in rugged applications is the combi oil seal.

It isn’t a flashy invention, but that’s the point. It's a practical, well-thought-out configuration made to address recurring issues in machines that run under pressure, vibration, and environmental exposure.

Built from Experience, Not Just Materials

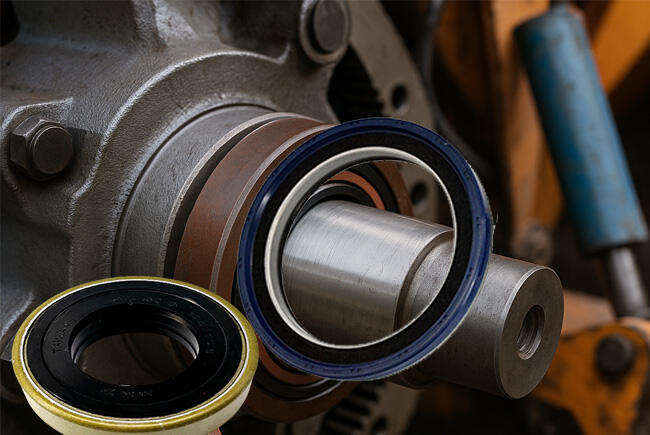

The basic idea behind a combi seal is pretty simple: instead of relying on a single lip or material to block contaminants and hold fluid, you use a layered design—often involving rubber, PTFE, and sometimes spring elements—to get better performance across more demanding conditions.

What makes this design useful is how it leverages different materials. The rubber provides elasticity and contact, while PTFE (polytetrafluoroethylene) gives the seal its edge in environments where things get hot, dirty, or corrosive.

Notably, PTFE’s ability to resist sticking is a huge bonus. Many users report that over time, seals without PTFE tend to gum up—especially where dust mixes with lubricants. PTFE holds up better, even when cycling back and forth repeatedly.

Where the Combi Seal Really Fits

· Heavy-duty transport and construction vehicles—particularly wheel hubs and axle joints that face dirt, shock, and speed.

· Agricultural machines like harvesters and planters—often operating in muddy or dusty fields.

· Industrial hydraulic systems—especially those where access is limited and breakdowns are costly.

· Wind turbines—where the yaw systems have to keep moving despite constant wind-blown sand and salt exposure.

· Metallurgy equipment—rolling lines, furnaces, or gearboxes where both temperature and debris are a constant.

What unites all these situations isn’t just harsh conditions—it’s the fact that replacing seals is either expensive, time-consuming, or both. That’s why long service life, low maintenance, and predictable wear behavior matter so much.

Not Just Theory—NQKSF Builds These with Purpose

At NQKSF, we’ve spent more than three decades working with OEMs, maintenance teams, and machine builders across different sectors. We don’t just sell combi seals—we help make sure they’re the right fit, both in size and in function.

Sometimes a customer comes to us thinking they need a high-temperature rubber seal, when the real issue is shaft misalignment or pressure spikes. In those cases, we help them choose a combi structure with a built-in PTFE element or a spring-load that can adapt to changes. It’s not about over-engineering—it’s about choosing the right setup for the job.

We keep over 10,000 different sealing parts in stock, including O-rings, traditional oil seals, and multiple configurations of combi seals. That allows us to ship standard products quickly and focus our engineering time on custom solutions where it matters most.

Real Customization Means Real Results

For us, customization doesn’t mean just changing the color of the rubber. It means:

· Selecting the best elastomer or PTFE grade for the media involved

· Adjusting lip geometry for speed, pressure, or directionality

· Designing for compact systems where space is at a premium

· Testing performance under cycling, vibration, or chemical exposure

With in-house simulation tools and full-scale test rigs, we can model how a seal will behave before it ever reaches your equipment. That’s saved several of our clients major downtime in the past—especially in cases where small errors in seal design led to gradual leakage or premature wear.

Backed by Facilities, Not Just Promises

We're proud of our intelligent manufacturing setup. From material inspection to final packing, the entire production line is under our own roof. That gives us full control over quality, delivery, and consistency.

We don’t just serve the domestic market either. Our seals are in operation in over 80 countries, and we’ve worked with several globally recognized equipment brands. We're also recognized as a High-Tech Enterprise and have been designated a Provincial Innovation Center in the sealing industry.

Let’s be clear—combi oil seals aren’t perfect for every situation. In slow-sliding applications where ultra-tight static sealing is needed, a different type of lip seal might be a better option. But if you’re dealing with systems that move, rotate, vibrate, or run through dirty conditions for hours every day—this is where the combi seal proves its worth.

The dual-material design cuts friction, handles pressure, resists wear, and helps reduce the frequency of replacement. That means fewer shutdowns, less troubleshooting, and more stable performance over time.

We don’t think of combi oil seals as just products—they’re part of an entire system that needs to work reliably. Whether it’s an excavator axle, a wind turbine yaw gear, or a robotic joint in a dusty factory, the right seal can make the difference.

At NQKSF, we combine real-world field knowledge, production control, and engineering service to support your sealing needs. We're here to help you get it right the first time—because we know what’s at stake when seals fail.

Hot News

Hot News