Κατανόηση του κρίσιμου ρόλου των προηγμένων λύσεων στεγανοποίησης στη σύγχρονη βιομηχανία

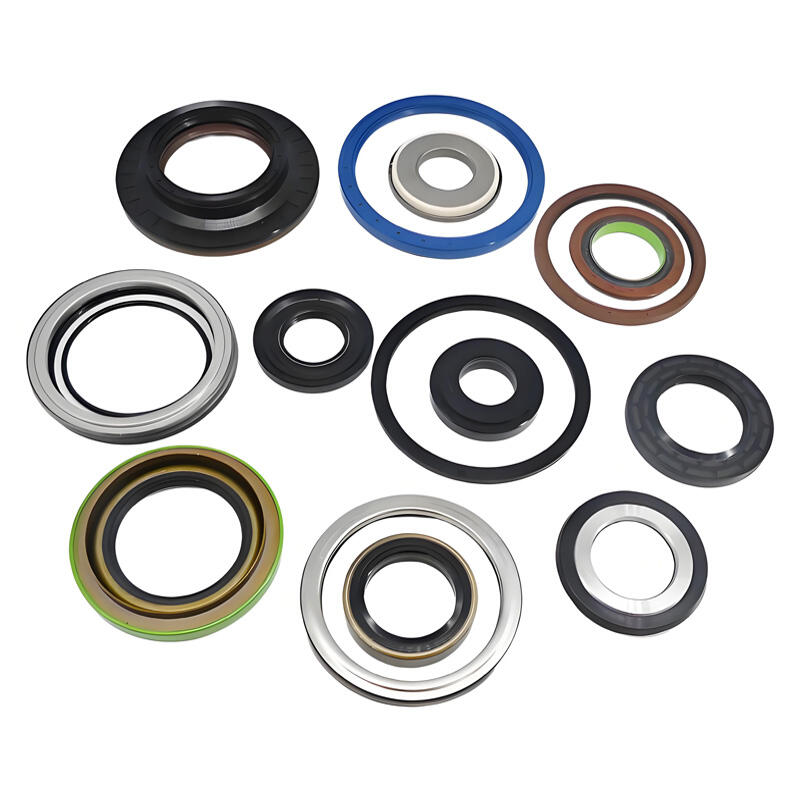

Στον απαιτητικό κόσμο των βιομηχανικών μηχανημάτων και εξοπλισμού, η αξιοπιστία και η απόδοση των εξαρτημάτων είναι καθοριστικής σημασίας για τη λειτουργική επιτυχία. Ανάμεσα σε αυτά τα κρίσιμα στοιχεία, σφράγιδες κύλινδρου με ακτινωτή διάταξη ξεχωρίζουν ως απαραίτητα εξαρτήματα που προστατεύουν τα έδρανα, διατηρούν τα λιπαντικά και αποτρέπουν τη μόλυνση σε περιστρεφόμενο εξοπλισμό. Αυτές οι εξελιγμένες λύσεις στεγανοποίησης έχουν εξελιχθεί σημαντικά τα τελευταία χρόνια, προσφέροντας ανεπίτρεπτα επίπεδα προστασίας και αποδοτικότητας σε διάφορες βιομηχανικές εφαρμογές.

Οι σύγχρονες διεργασίες παραγωγής και οι τεχνολογικές εξελίξεις έχουν επαναστατήσει τον τρόπο σχεδιασμού και εφαρμογής των ακτινικών στεγανωτικών άξονα. Αυτές οι καινοτομίες έχουν οδηγήσει σε σημαντικές βελτιώσεις στην απόδοση, την ανθεκτικότητα και τη συνολική αξιοπιστία του εξοπλισμού. Καθώς οι βιομηχανίες συνεχίζουν να διευρύνουν τα όρια της λειτουργικής αποδοτικότητας, ο ρόλος των υψηλής απόδοσης ακτινικών στεγανωτικών άξονα γίνεται όλο και πιο σημαντικός για τη διατήρηση της βέλτιστης λειτουργικότητας του εξοπλισμού.

Αύξηση της Προστασίας και της Αξιοπιστίας του Εξοπλισμού

Ανώτερη Πρόληψη Εμπορικής

Τα υψηλής απόδοσης ακτινικά στεγανωτικά άξονα εξακονίζουν στη δημιουργία αδιαπέραστου φραγμού κατά των εξωτερικών ρύπων. Σε σκληρά βιομηχανικά περιβάλλοντα, όπου η σκόνη, τα υλικά και η υγρασία αποτελούν συνεχείς απειλές, αυτά τα στεγανωτικά διατηρούν την ακεραιότητά τους για να προστατεύσουν ζωτικά εξαρτήματα εξοπλισμού. Τα προηγμένα υλικά και η ακριβής μηχανική σχεδίαση διασφαλίζουν ότι ακόμη και τα μικροσκοπικά σωματίδια αποκλείονται αποτελεσματικά, μειώνοντας σημαντικά τον κίνδυνο ζημιάς του εξοπλισμού και πρόωρης βλάβης.

Η ικανότητα του στεγανωτικού να διατηρεί σταθερή πίεση επαφής προς τον άξονα, ακόμη και υπό μεταβαλλόμενες συνθήκες λειτουργίας, διασφαλίζει αξιόπιστη προστασία καθ' όλη τη διάρκεια της χρήσης του. Αυτό το σταθερό προστατευτικό φράγμα έχει ως αποτέλεσμα τη μείωση των αναγκών συντήρησης και την επέκταση της διάρκειας ζωής του εξοπλισμού.

Βέλτιστη Διατήρηση Λιπαντικού

Μία από τις πιο σημαντικές λειτουργίες των ακτινικών στεγανωτικών αξόνων είναι η διατήρηση του κατάλληλου λιπαντικού μέσα στα μηχανικά συστήματα. Τα στεγανωτικά υψηλής απόδοσης διακρίνονται σε αυτόν τον τομέα, καθώς αποτρέπουν αποτελεσματικά τη διαρροή λιπαντικού, ακόμη και σε συνθήκες υψηλής πίεσης. Αυτή η ανωτέρα ικανότητα συγκράτησης διασφαλίζει ότι οι τριβείς και άλλα κρίσιμα εξαρτήματα παραμένουν κατάλληλα λιπασμένα, ελαχιστοποιώντας την τριβή και τη φθορά.

Τα οικονομικά οφέλη από τη βελτιωμένη συγκράτηση λιπαντικού είναι σημαντικά, καθώς μειώνεται η συχνότητα αλλαγής λαδιού και ελαχιστοποιείται η περιβαλλοντική επίπτωση από διαρροές. Αυτή η αποδοτικότητα συμβάλλει σημαντικά σε βιώσιμες βιομηχανικές πρακτικές, ενώ μειώνει το λειτουργικό κόστος.

Προηγμένη Τεχνολογία Υλικών και Χαρακτηριστικά Σχεδίασης

Καινοτόμες Συνθέσεις Υλικών

Οι σύγχρονα ακτινικά στεγανωτικά άξονες χρησιμοποιούν εξελιγμένες ελαστομερείς ενώσεις που σχεδιάζονται ειδικά για ακραίες συνθήκες. Αυτά τα υλικά προσφέρουν εξαιρετική αντοχή σε μεταβολές θερμοκρασίας, χημικής έκθεσης και μηχανικής τάσης. Η ανάπτυξη ειδικών ενώσεων φθοροελαστομέρους και πολυακρυλικών έχει επαναστατήσει την απόδοση των στεγανωτικών σε δύσκολα βιομηχανικά περιβάλλοντα.

Αυτά τα υλικά διατηρούν τις φυσικές τους ιδιότητες και τη στεγανοποίηση αποτελεσματικότητα ακόμη και όταν εκτίθενται σε επιθετικά μέσα, υψηλές θερμοκρασίες ή γρήγορες αλλαγές πίεσης. Το αποτέλεσμα είναι επεκταμένη διάρκεια ζωής του στεγανωτικού και πιο αξιόπιστη λειτουργία του εξοπλισμού σε διάφορες βιομηχανικές εφαρμογές.

Ακριβής Μηχανική και Κατασκευή

Η διαδικασία παραγωγής υψηλής απόδοσης ακτινικών σφραγίδων αξόνων χρησιμοποιεί εξελιγμένη τεχνολογία για να επιτευχθεί απροηγούμενο επίπεδο ακρίβειας. Ο σχεδιασμός με τη βοήθεια υπολογιστή και οι προηγμένες τεχνικές παραγωγής εξασφαλίζουν συνεχή ποιότητα και βέλτιστη γεωμετρία σφράγισης. Αυτή η ακρίβεια είναι κρίσιμη για τη διατήρηση της κατάλληλης επαφής με τον άξονα και για την αξιόπιστη λειτουργία υπό διαφορετικές συνθήκες λειτουργίας.

Οι σύγχρονες μέθοδοι παραγωγής επιτρέπουν επίσης την προσαρμογή των προφίλ των σφραγίδων για να πληρούνται οι συγκεκριμένες απαιτήσεις εφαρμογής, βελτιστοποιώντας την απόδοση για συγκεκριμένες συνθήκες λειτουργίας και προδιαγραφές εξοπλισμού.

Λειτουργική Αποδοτικότητα και Οικονομικά Μειονεκτήματα

Μειωμένα απαιτήματα διατήρησης

Οι υψηλής απόδοσης ακτινικές σφραγίδες αξόνων μειώνουν σημαντικά τη συχνότητα των συντηρητικών παρεμβάσεων. Η ανωτέρα ανθεκτικότητα και αξιόπιστη λειτουργία τους σημαίνει λιγότερες αντικαταστάσεις σφραγίδων και λιγότερες διακοπές λειτουργίας του εξοπλισμού. Η μείωση αυτή στις απαιτήσεις συντήρησης μεταφράζεται απευθείας σε εξοικονόμηση κόστους και βελτίωση της παραγωγικότητας για τις βιομηχανικές εγκαταστάσεις.

Η παρατεταμένη διάρκεια ζωής αυτών των στεγανοποιήσεων μειώνει επίσης το συνολικό κόστος ιδιοκτησίας για βιομηχανικό εξοπλισμό, καθιστώντας τις μια οικονομικά αποδοτική επιλογή παρά την αρχικά υψηλότερη επένδυση σε σύγκριση με τις συμβατικές στεγανοποιήσεις.

Διατήρηση Ενέργειας και Βιωσιμότητα

Οι σύγχρονες ακτινικές στεγανοποιήσεις ατράκτου σχεδιάζονται με χαρακτηριστικά μειωμένης τριβής, συμβάλλοντας στη μείωση της κατανάλωσης ενέργειας σε περιστρεφόμενο εξοπλισμό. Η βελτιωμένη αυτή απόδοση μειώνει όχι μόνο τα λειτουργικά κόστη, αλλά επίσης υποστηρίζει τους στόχους περιβαλλοντικής βιωσιμότητας. Η μειωμένη τριβή παράγει επίσης λιγότερη θερμότητα, συμβάλλοντας σε καλύτερη συνολική απόδοση και διάρκεια ζωής του συστήματος.

Επιπλέον, οι ανωτέρω δυνατότητες στεγανοποίησης αποτρέπουν τη διαρροή λιπαντικού, μειώνοντας το περιβαλλοντικό αντίκτυπο και υποστηρίζοντας τη συμμόρφωση με τους όλο και πιο αυστηρούς περιβαλλοντικούς κανονισμούς.

Εφαρμογή και Εφαρμογή Εποπτεύξεις

Καλές Πρακτικές Επιλογής και Εγκατάστασης

Η σωστή επιλογή αξονικών στεγανωτικών απαιτεί προσεκτική εξέταση των συνθηκών λειτουργίας, όπως η ταχύτητα, η θερμοκρασία, η πίεση και η συμβατότητα με το υλικό. Η διαβούλευση με ειδικούς και η εξονυχιστική ανάλυση των απαιτήσεων της εφαρμογής διασφαλίζουν τη βέλτιστη απόδοση και αξιοπιστία του στεγανωτικού. Η διαδικασία εγκατάστασης πρέπει να ακολουθεί ακριβείς διαδικασίες για να αποφευχθεί ζημιά και να εξασφαλιστεί η σωστή λειτουργικότητα.

Πρέπει να εγκαθίστανται πρωτόκολλα τακτικής παρακολούθησης και συντήρησης για τη μεγιστοποίηση των πλεονεκτημάτων των υψηλής απόδοσης στεγανωτικών. Αυτό περιλαμβάνει περιοδικό έλεγχο των προτύπων φθοράς και της κατάστασης του στεγανωτικού για την πρόβλεψη και την πρόληψη πιθανών βλαβών.

Ειδικές Εφαρμογές Βιομηχανίας

Οι διάφορες βιομηχανίες έχουν ιδιαίτερες απαιτήσεις ως προς τα αξονικά στεγανωτικά. Τα μηχανήματα βαρέος μεταλλείου μπορεί να δίνουν προτεραιότητα στην ανθεκτικότητα και την ανθεκτικότητα στη μόλυνση, ενώ οι εφαρμογές επεξεργασίας τροφίμων απαιτούν υλικά σύμφωνα με τις προδιαγραφές της FDA και ανωτέρα υγιεινή χαρακτηριστικά. Η κατανόηση αυτών των συγκεκριμένων αναγκών είναι κρίσιμη για την επιλογή της κατάλληλης διαμόρφωσης του στεγανωτικού.

Η ευελιξία των σύγχρονων αξονικών στεγανωτικών ακτινικού τύπου τα καθιστά κατάλληλα για διάφορες εφαρμογές, από υψηλής ταχύτητας βιομηχανικές αντλίες μέχρι αργά κινούμενα γεωργικά μηχανήματα, με κάθε εφαρμογή να επωφελείται από τα προηγμένα χαρακτηριστικά και την αξιοπιστία τους.

Συχνές Ερωτήσεις

Πόσο διάρκεια ζωής έχουν συνήθως τα υψηλής απόδοσης αξονικά στεγανωτικά ακτινικού τύπου;

Η διάρκεια ζωής των υψηλής απόδοσης αξονικών στεγανωτικών ακτινικού τύπου ποικίλλει ανάλογα με τις συνθήκες λειτουργίας, αλλά συνήθως διαρκούν 2-3 φορές περισσότερο από τα συμβατικά στεγανωτικά, όταν εγκατασταθούν και συντηρηθούν σωστά. Σε ιδανικές συνθήκες, μπορούν να λειτουργούν αποτελεσματικά για αρκετά χρόνια.

Ποιοι είναι οι βασικοί παράγοντες που επηρεάζουν την απόδοση των αξονικών στεγανωτικών ακτινικού τύπου;

Κρίσιμοι παράγοντες περιλαμβάνουν τη θερμοκρασία λειτουργίας, την ταχύτητα του άξονα, τη διαφορά πίεσης, τη συμβατότητα με το λιπαντικό, την επιφανειακή κατάσταση του άξονα και τις περιβαλλοντικές συνθήκες. Η σωστή ευθυγράμμιση και εγκατάσταση είναι επίσης απαραίτητες για τη βέλτιστη απόδοση.

Μπορούν τα υψηλής απόδοσης αξονικά στεγανωτικά ακτινικού τύπου να χρησιμοποιηθούν σε ακραίες θερμοκρασίες;

Ναι, υπάρχουν σύγχρονα στεγανωτικά υψηλής απόδοσης από ειδικά υλικά που έχουν σχεδιαστεί για να αντέχουν ακραίες θερμοκρασίες, από -40°C έως +200°C ή και περισσότερο, ανάλογα με τη συγκεκριμένη σύνθεση του υλικού και τις απαιτήσεις της εφαρμογής.

Πίνακας Περιεχομένων

- Κατανόηση του κρίσιμου ρόλου των προηγμένων λύσεων στεγανοποίησης στη σύγχρονη βιομηχανία

- Αύξηση της Προστασίας και της Αξιοπιστίας του Εξοπλισμού

- Προηγμένη Τεχνολογία Υλικών και Χαρακτηριστικά Σχεδίασης

- Λειτουργική Αποδοτικότητα και Οικονομικά Μειονεκτήματα

- Εφαρμογή και Εφαρμογή Εποπτεύξεις

- Συχνές Ερωτήσεις