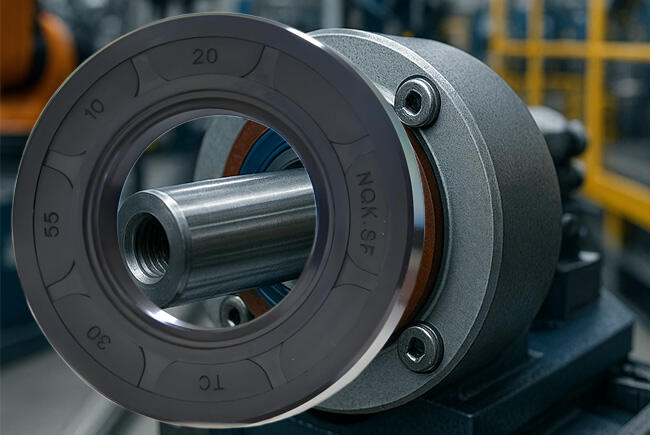

In dynamic mechanical systems, sealing reliability is not just a performance factor—it is a fundamental requirement. The Double Lip Shaft Oil Seal series has become a go-to solution for applications where both contamination prevention and lubricant retention are critical. Designed with two lips—one primary and one secondary—these seals offer added protection in high-speed rotary conditions and harsh environments, ensuring system longevity and operational stability.

Why Double Lip Designs Matter

The dual-lip configuration provides a distinct advantage over single lip seals. While the primary lip serves the usual role of preventing oil or grease from leaking, the secondary lip acts as a dust barrier, keeping contaminants such as water, dirt, or debris from infiltrating the system. This makes the double lip shaft oil seal especially suitable for industries that experience aggressive operating conditions or outdoor exposure.

Application Scope Across Industries

Double lip shaft oil seals are extensively used in:

· Gearboxes and Transmissions

· Hydraulic Pumps and Motors

· Industrial Electric Motors

· Agricultural and Construction Machinery

· Wind Power Systems

· Heavy-Duty Trucks and Automotive Engines

· Marine and Rail Equipment

· Metallurgical and Chemical Machinery

· Industrial Robotics and Automated Arms

In all these applications, the ability to balance fluid retention with environmental protection is vital—something the double lip design excels at.

Materials and Durability

NQKSF is double lip shaft seals are available in materials such as NBR (nitrile rubber), FKM (fluorocarbon rubber), and silicone blends, depending on the application temperature, media, and dynamic speed. Reinforced with stainless steel or carbon steel garter springs and frames, the seals demonstrate excellent resistance to wear, pressure fluctuations, and chemical attack.

These material options make them adaptable to both low-speed and high-speed rotating shafts, as well as dry or submerged conditions. The result is a longer lifecycle and reduced maintenance intervals.

NQKSF is Commitment to Engineering Excellence

With over 30 years of expertise, NQKSF doesn’t just offer a product—we deliver an engineered solution. Our technical empowerment services help customers optimize sealing systems, improving durability and reducing maintenance costs. Through simulation support, material guidance, and testing validation, our team collaborates closely with clients to meet unique performance benchmarks.

Three-Tier Service Model

Ready-to-Ship Standard Inventory

With over 10,000 specifications in stock—including O-rings, shaft seals, and customized sealing parts—we respond rapidly to urgent procurement needs, helping clients minimize downtime.

Tailored Engineering Support

From material selection and design refinement to mold manufacturing and testing, our end-to-end customization ensures your seal is fully aligned with the operating environment.

Performance Optimization Partnership

Leveraging deep application knowledge and industry standards, NQKSF aids clients in building smarter, more sustainable equipment through sealing innovations.

What Sets NQKSF Apart

Physical manufacturing base with precision automation

· Wide model availability and large-scale warehousing

· Global reach across 80+ countries

· Recognized by global equipment brands

· Provincial Tech Innovation Center accreditation

· "Specialized and New" provincial enterprise recognition

· Certified high-tech enterprise

· Leading company in specialized industrial clusters

These credentials reflect our long-standing dedication to quality, innovation, and customer satisfaction.

Who Benefits From the Double Lip Shaft Oil Seal?

If you're in any of the following sectors, this seal is likely a key component in your equipment:

· Industrial automation (robotic arms, CNC systems)

· Renewable energy (wind turbines, hydroelectric systems)

· Engine-driven equipment (trucks, tractors, ships, and locomotives)

· Fluid-driven systems (pumps, compressors, gear units)

· Heavy industry (foundries, chemical processors)

· Agricultural machinery (harvesters, irrigation systems)

In applications where dust, fluid, vibration, and speed intersect, the Double Lip Shaft Oil Seal offers a balanced and robust sealing approach. Backed by NQKSF is global supply capability, engineering depth, and technical precision, it continues to be the preferred solution across industries.

Whether you're seeking fast delivery of standard sizes or in-depth customization for demanding environments, NQKSF is ready to support your sealing strategy.

Hot News

Hot News