Gjennom over tre tiår med arbeid med tetting løsninger, er ett gjentatt spørsmål kommet tilbake fra kunder: Finnes det en tetting som kan overleve i trange rom, under trykkfluktuasjoner, uten å slites for raskt?

Svaret er ikke ett enkelt produkt, men snarere en designtilnærming. Det er her kombinasjonstettet-serien kommer inn.

Hva er en Kombinasjonslås ?

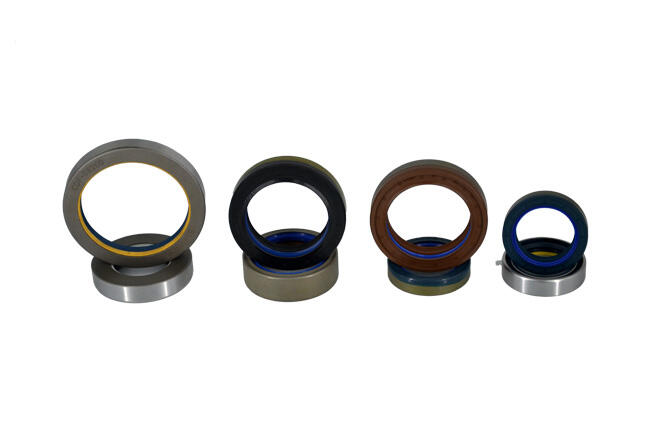

I stedet for å stole på ett tettingselement, integrerer en kombinasjonstettet to eller flere materialer eller geometrier i en kompakt enhet. Hver del bidrar med noe forskjellig: ett lag kan gi elastisitet og stram passform, mens et annet sikrer lav friksjon og holdbarhet.

Et vanlig eksempel er i hydrauliske sylindere. Å stole utelukkende på en O-ring eller en leppeforseglingsring vil ikke vare lenge under høye belastninger. Men å kombinere PTFE med en elastomer energisørger for en langt mer holdbar løsning. PTFE gir slitasjemotstand og lav friksjon, mens elastomeren sikrer tett kontakt med sporet. Denne hybridkonstruksjonen er hvorfor mange i industrien rett og slett kaller dem «kombinasjonsforseglinger».

Hvorfor ingeniører velger dem

Styrken til kombinasjonsforseglinger er mangfoldigheten.

· Materialer: alternativene spenner over NBR, FKM og polyuretan til fylt PTFE. Blandingen kan tilpasses driftsmiljøet – uansett om det betyr høye temperaturer, aggressive medier eller slitasjefulle forhold.

· Trykkhåndtering: mens standard hydrauliske forseglinger ofte når sitt maks ved moderate belastninger, kan kombinasjonsforseglinger arbeide komfortabelt i systemer som når og overstiger 35 MPa.

· Kompakt design: når det ikke er ekstra plass i huset, leverer den kombinerte tetningen fortsatt både tetnings- og førefunksjoner i en kompakt profil.

Kort fortalt gir disse tetningene konstruktører pusterom: høyere ytelse uten å kreve større hus.

Leksjoner fra feltet

Et godt eksempel kom fra et prosjekt med hovedaksel i en vindturbin som vi håndterte for noen år siden. Kunden hadde prøvd enkeltleppetetninger, men etter bare seks måneder slitasje ut tetningene og lekkasje begynte. Vi omkonstruerte tetningssystemet med en polyuretan ytterring og en FKM O-ring energisert innvendig. Resultatet? Levetiden ble fordoblet, og uplanlagt nedetid ble halvert.

Dette er det som overbeviser ingeniører og distributører likt: det handler ikke om en katalogdel, men om å tilpasse tetningen til den reelle miljøet.

Ved å snakke med dusinvis av forhandlere og grossister, kommer tre prioriteringer opp igjen og igjen:

· Hastighet – lagerplassering og rask avsending gjør eller bryter en leverekette.

· Skreddersying – mange sluttbrukere står ovenfor unike dimensjoner; leverandøren må være i stand til å tilpasse seg.

· Teknisk support – å ha eksperter å snakke med om et problem er like viktig som selve produktet.

Ved NQKSF har disse punktene formet vår måte å arbeide på. Vi har tusenvis av O-ringer, tetninger og sett på lager for umiddelbar levering. Vi håndterer også spesialproduksjoner, fra valg av materiale til prototype-testing. Og med over 30 års erfaring fra praktiske prosjekter, kan vårt team foreslå systemvise optimaliseringer, ikke bare levere en delenummer.

Hvorfor NQKSF?

Tetningsmarkedet er overfylt. Hvorfor velger da globale merker og lokale distributører å fortsette samarbeidet med oss?

· Vi er et produksjonsselskap, ikke en ren handelskontor, slik at produksjon og levering er under direkte kontroll.

· Anerkjent som en av ledende aktører innen tetningsteknologi, med et komplett produktsortiment og bred lagerhold.

· Produkter forhandles til over 80 land, og levere både OEM- og aftermarkedsbehov.

· Sertifisert som et provinsielt teknologisenter for innovasjon, spesialisert og innovativt selskap, og høyteknologisk selskap.

· Plassert i ett av Kinas mest avanserte industrikluster, noe som gir oss tilgang til sterk leverandørstøtte.

Dette er ikke bare emblemmer; de viser hvordan kunder opplever en jevnere samarbeidsprosess. En gang fortalte en utenlandsk grossist meg at hovedgrunnen til at de valgte oss, var enkel: «Når vi støter på et problem, er det noen som løser det, i stedet for å skyve ansvaret videre».

Hvor de brukes

Kombinasjonstetninger finnes overalt hvor utstyr ikke kan tillate lekkasje eller nedetid:

· Hydrauliske pumper og motorer

· Girkasser og motorer

· Bygge- og landbruksmaskineri

· Metallurgi- og kjemisk utstyr

· Vindturbiner og fornybar energi

· Transport: jernbane, sjøfart, tunge lastebiler

Alle disse sektorene deler en realitet – nedetid er kostbar. En liten tetningsfeil kan føre til enorme vedlikeholdskostnader. Rollen til kombinasjonstetninger er å minimere dette risikoen.

Spørsmål kjøpere ofte stiller

Sp: Kan kombinasjonstetninger erstatte O-ringer?

Sv: Ikke helt. O-ringer er fremdeles den mest universelle løsningen, men når trykket er høyt eller bevegelsen er stor, er kombinasjonstetninger mer pålitelige.

Sp: Hva med leveringstider for partiforhandlere?

Sv: Standardvarer sendes samme dag. Tilpassede løsninger tar vanligvis to til tre uker.

Sp: Hvordan hjelper dere grossister med å unngå overlagring?

Sv: Vi tilbyr delte leveranser og rådgivning om hvilke dimensjoner som er mest etterspurt, slik at lageret beholdes helse.

Kombinasjonstetninger er ikke en helt ny oppfinnelse, men de fyller hullene som tradisjonelle enkeltdelstetninger ikke kan. For utstyrsprodusenter betyr de pålitelighet. For grossister betyr de sterkere konkurranseevne. For oss i tetningsbransjen representerer de en smartere måte å tenke på – å utnytte materialer og design, fremfor å fremheve et enkelt produkt.

Siste nytt

Siste nytt