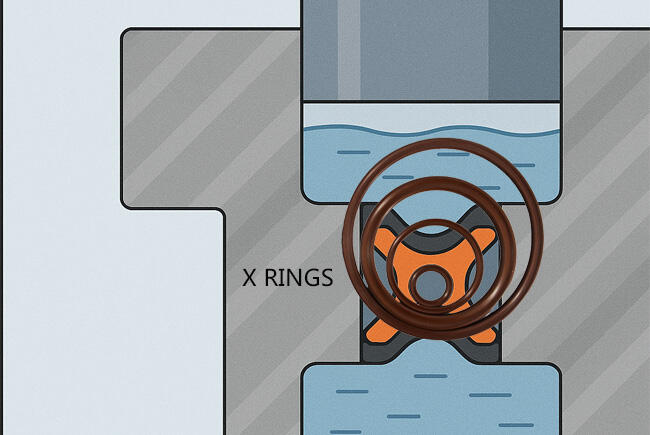

The unique four-lip design of the x ring, with a cross-section shaped like an "X", has significant advantages over traditional o-rings. Its optimized geometry forms a micro-lubricant reservoir between the sealing lips, significantly reducing friction and starting resistance. This reduces energy consumption, extends seal life, and enables smoother operation in reciprocating systems. Crucially, the x-shaped profile eliminates the common rolling tendency of round seals during dynamic movement, ensuring continuous contact and preventing leakage paths. In addition, the cleverly designed parting line (burr) is located in the groove, which enhances the sealing effect.

1. Application environment of x rings:

· Hydraulic and pneumatic: Its low friction and stability make it an ideal sealing material for pistons, piston rods and cylinders in hydraulic pumps, valves and actuators in applications such as industrial machinery, construction equipment (excavators, loaders), agricultural machinery (tractors, combine harvesters) and heavy trucks.

· Automotive and transportation: Widely used in transmission components, engine subsystems, steering systems and braking systems of automobiles, buses, trains (high-speed rail components) and aircraft landing gear mechanisms, providing reliable dynamic sealing under different pressures and temperatures.

·Industrial Automation and Robotics: It is critical for sealing precision linear actuators, joints and rotary shafts in robotic arms and automated machinery, where minimal stick-slip and stable performance are critical.

·Energy and Heavy Industry: Suitable for pumps, valves and compressors in wind turbine pitch control systems, oil and gas equipment, water treatment plants, and harsh environments in metallurgical and chemical processing.

2. How to choose a x ring?

Material: The choice of material determines the performance limit. Nitrile rubber (NBR), with excellent oil/fuel resistance, is a common general choice;. For extreme temperatures (-20°C to +250°C) or corrosive chemicals, fluororubber (FKM) and ethylene-propylene rubber (EPDM) can be selected.

3. Application characteristics

Static and reciprocating seals: For hole (gland) seals, the inner diameter of the x ring should be closely matched or slightly smaller than the groove diameter for better pre-compression. For shaft seals, the inner diameter of the x ring should match the shaft diameter or be slightly larger to facilitate installation and reduce radial stress during use.

Rotary seals: The inner diameter of the x ring must be larger than the shaft diameter to compensate for the Joule effect - the tendency of elastomers to thermally shrink under the friction heat generated by rotation. Adequate lubrication in this slightly enlarged gap is important for reliable rotation performance.

NQKSF: Your Sealing Partner

We know that customers not only need high-quality products, but also professional knowledge and fast response support.

As a professional modern entity intelligent manufacturing enterprise integrating design, research and development, manufacturing, sales of oil seals and o-rings and various types of sealing products, more than 200 advanced production and testing equipment, using SAP is ERP management system, strictly implementing ISO 9001 and TS16949 international management system certification standards. Achieved paperless, networked, transparent and timely office.

We are the leader in the sealing industry, with a full range of models and stock, and can provide timely quotations, strict production, quality assurance, and on-time delivery. This differentiates it from the chaotic prices and uneven quality in the market. With these advantages, NQKSF has spread all over the world in the field of seals.

X rings alleviate the limitations of o-rings in dynamic environments, thereby reducing friction and improving stability and reliability. Working with a supplier with strong technical capabilities such as NQKSF can ensure that you get high-performance x rings (standard or customized).

Hot News

Hot News