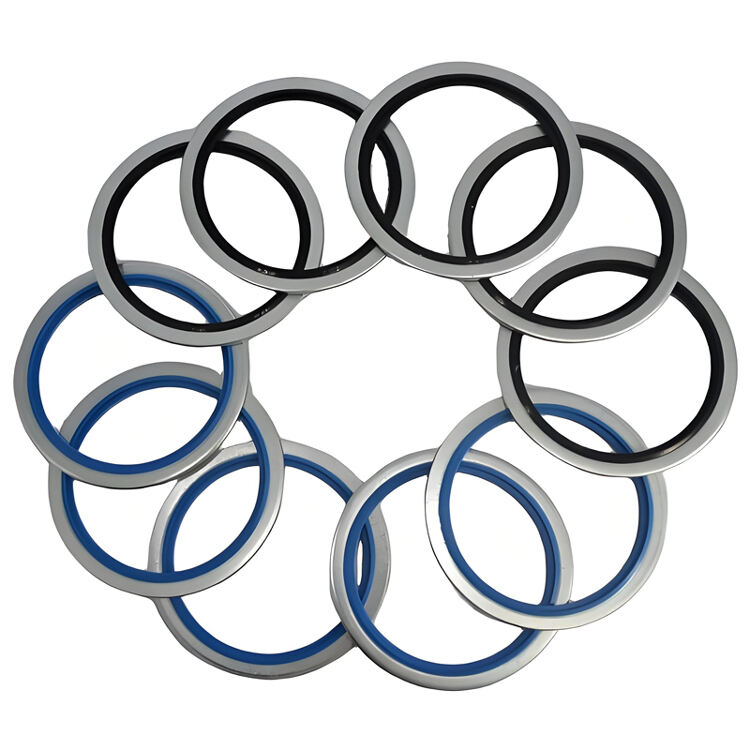

Double-lip Radial Shaft Seal

Double‑lip design for stronger contamination control and up to 15% lower friction. Explore full specifications or contact us for more details.

- Overview

- Related Products

The Double-lip Radial Shaft Seal is a crucial component used in various industries to prevent lubricant leakage and contamination. Featuring a dual-lip design, it provides enhanced sealing performance compared to single-lip seals. This dual lip structure helps to reduce leaks and protect sensitive components from dirt, dust, and moisture, ensuring longevity and reliability of rotating machinery.

Advantages

Dual‑lip Structure for Enhanced Protection

The secondary lip helps reduce the entry of dust and moisture compared with single‑lip seals, supporting more stable sealing performance in demanding environments.

Lower Friction, More Predictable Wear

The optimized lip profile helps reduce friction by around 10–15% (reference value), contributing to smoother shaft rotation and more consistent wear behavior.

Improved Contamination Control

The dust lip forms an additional barrier, helping limit particle intrusion in outdoor or dusty working conditions.

Dimensional Stability Under Load

The metal case provides structural support, helping the seal maintain its shape during temperature changes and shaft vibration.

Specifications

| Item | Specification |

| Product Type | Double‑lip Radial Shaft Seal |

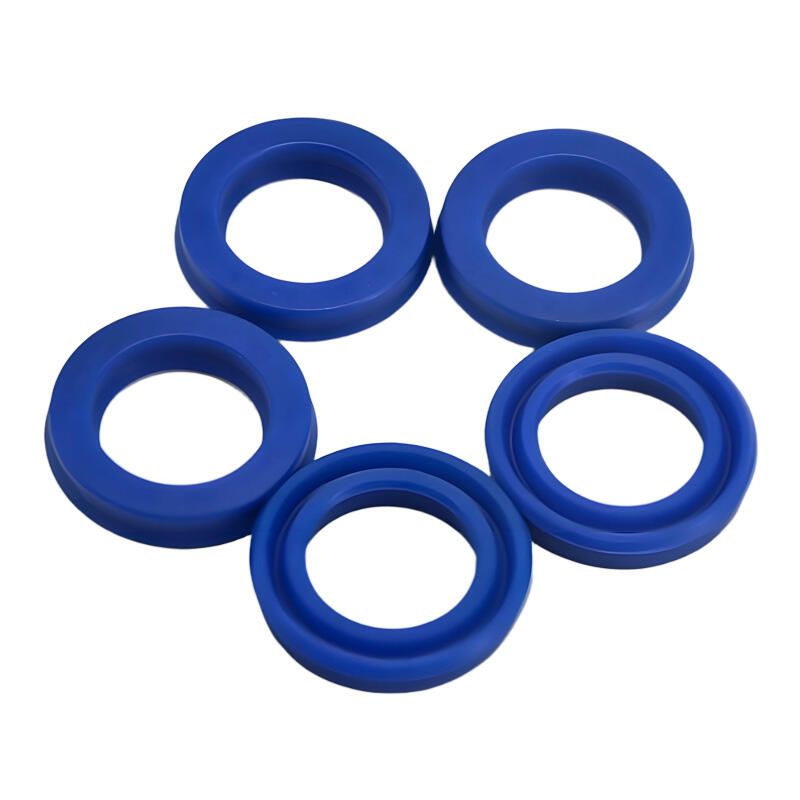

| Lip Structure | Primary Lip + Dust Lip |

| Material Options | NBR / FKM |

| Temperature Range | -40°C to 250°C (depending on the material) |

| Metal Case | Carbon Steel / Stainless Steel |

| Hardness | 70–90 Shore A |

| Size Range | 3–1000 mm |

| Suitable Media | Lubricating Oil / Grease |

Applications

Hydraulic Systems: The Double‑lip Radial Shaft Seal helps maintain stable oil pressure by reducing leakage around rotating shafts. The dust lip also limits the entry of fine particles commonly found in hydraulic environments, supporting smoother system response.

Industrial Fans & Blowers: In high‑airflow equipment, airborne dust can easily reach the shaft area. The dual‑lip structure provides an added barrier, helping protect bearings and extending service intervals.

Conveying Equipment: Conveyors used in packaging, mining, or material‑handling operations often run in dusty surroundings. The Double‑lip Radial Shaft Seal helps prevent contaminants from entering the bearing chamber, supporting consistent operation.

Compressors: Compressors operate under fluctuating pressure and temperature. The dual‑lip design helps retain lubricant while limiting moisture intrusion, contributing to more predictable sealing behavior.

Service

Technical Support

Assistance with material selection, installation guidance, and application matching.

Customization Options

Non‑standard sizes, materials, and lip structures can be produced based on drawings or samples.

Quality Assurance

Each batch undergoes dimensional checks, material verification, and sealing performance testing.

FAQ

Q1: When should I choose a Double‑lip Radial Shaft Seal?

It is recommended when equipment operates in dusty, humid, or outdoor environments where additional contamination control is needed.

Q2: Can you customize sizes or materials?

Yes. Custom dimensions and material combinations can be produced according to drawings or samples.

Q3: What factors influence seal lifespan?

Shaft surface finish, installation method, operating temperature, and lubricant type all affect service life.