Разбирање на критичната улога на напредната техника на запечатување во индустријската опрема

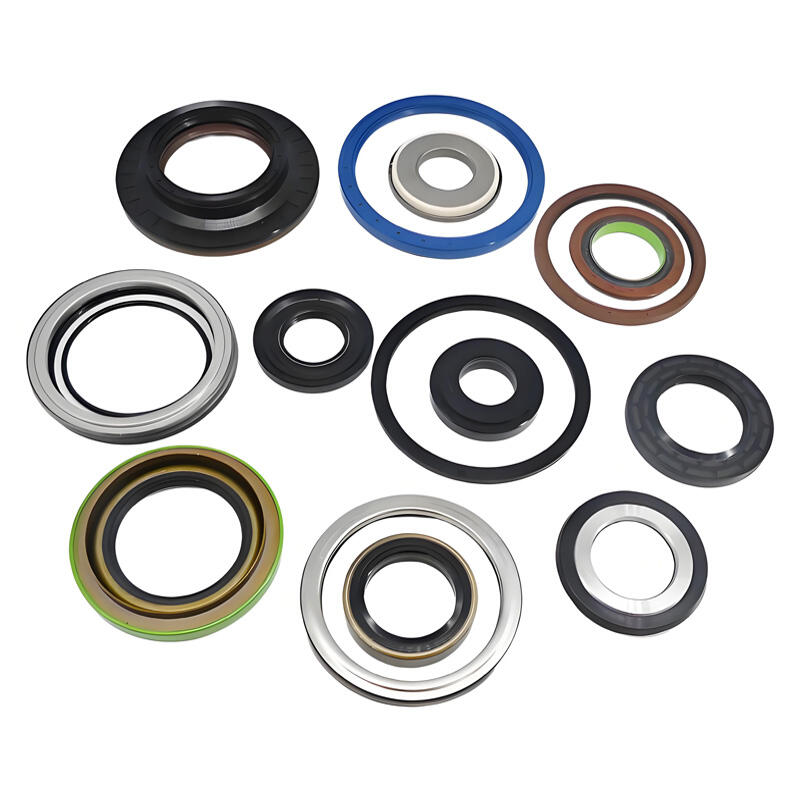

Во захтевниот свет на индустријската машинерија, ротационите саленки под висок притисок заптивања на вратило претставуваат темел на оперативната сигурност и долговечноста на опремата. Овие напредни компоненти служат како чувари на критични механички системи, спречувајќи губење на подмазување и контаминација, при тоа одржувајќи оптимални перформанси под екстремни услови. Без оглед дали станува збор за рударска опрема, тешка градежна машинерија или индустријски обработни погони, овие саленки постојано се соочуваат со предизвиците поврзани со управување со висока брзина на ротација и истовремено задржување на значителни разлики во притисок.

Значењето на седлата за ротирачки вратила со висок притисок надминува многу нивната скромна големина. Тие се конструирани да издржат интензивен механички напон, термални варијации и агресивни медиуми, при тоа задржувајќи ја целоста на затворањето. Во денешниот индустриски пејзаж, каде што застојот на опремата може да резултира со значителни финансиски загуби, улогата на овие седла станува сé поважна за одржување на непрекинатите операции и заштита на вредните инвестиции во машини.

Основни компоненти и карактеристики на дизајнот

Иновација и избор на материјал

Развојот на седлата за ротирачки вратила со висок притисок бил поттикнат од напредокот во материјалната наука. Современите седла користат специјализирани еластомери и термопластични материјали кои нудат посилна отпорност на трошење, екстремни температури и хемиска изложеност. Овие материјали се внимателно одбрани според специфичните барања за примена, работните услови и еколошките фактори.

Напредните полимери како што се соединенијата на ПТФЕ, флуороеластомери и конструирани термопластик материјали обезбедуваат исклучителна трајност при задржување на ниски карактеристики на триење. Интегрирањето на овие материјали со прецизни техники за производство осигурува оптимални перформанси на седлата и подолг век на траење во барања индустријски апликации.

Геометриски конфигурации и инженерство на површини

Ефикасноста на ротационите седла за висок притисок во голема мера зависи од нивниот геометриски дизајн и површински карактеристики. Современите профили на седлата вклучуваат софистицирани конфигурации на усни, внимателно конструирани агли на контакт и прецизни завршни површини кои заедно работат за да осигураат сигурно затворање под динамички услови.

Површинските третмани и преклоци дополнително ја подобруваат перформансата на затвора со намалување на триењето, подобрување на отпорноста на трошење и овозможување правилно подмазнување. Овие инженерски аспекти се од суштинско значење за управување со деликатниот баланс помеѓу ефикасноста на затворањето и минималните губитоци на моќ преку триење.

Перформансни предности во индустријски примени

Подобрена заштита на опремата

Запечатувањата за ротирачки оски под висок притисок служат како прва линија на одбрана против контаминација и губење на подмазка кај критичната опрема. Нивната способност да ја задржат целоста на запечатувањето под екстремни услови на притисок спречува прематурно расипување на лежиштата, ги намалува захтевите за одржување и го продолжува векот на траење на опремата. Оваа заштита е особено важна во средини каде опремата работи непрекинато под тешки товари.

Со ефикасно задржување на подмазочните средства и исклучување на загадувачите, овие седла помагаат во одржувањето на оптимални услови за работа на лежиштата, влечковите и другите критични компоненти. Оваа заштитна функција директно се преведува во намалени трошоци за одржување и подобрување на сигурноста на опремата.

Подобрување на оперативната ефикасност

Употребата на ротациони седла со висок квалитет значително придонесува за вкупната ефикасност на системот. Современите конструкции на седлата минимизираат губитоците од триење, при тоа одржувајќи ефикасно запечатување, што резултира со намалена потрошувачка на енергија и подобрување на енергетската ефикасност. Овој баланс е особено важен кај апликации со висока брзина, каде губитоците од триење можат значително да ја засегнат работната економија.

Современите конструкции на седлата исто така овозможуваат подобро распрснување на топлината и распределба на подмазувањето, придонесувајќи за постабилни работни температури и подобрена долготрајност на компонентите. Овие предности директно влијаат врз конечната добивка преку намалена потрошувачка на енергија и подобрена перформанса на опремата.

Размислување за инсталација и одржување

Правилни Процедури за Инсталирање

Успехот на ротационите седла за висок притисок во голема мера зависи од правилните практики при монтажа. Правилна порамнетост, чистота и техника на монтажа се критични фактори кои влијаат врз перформансите и долготрајноста на седлото. Алатките и постапките за монтажа мора внимателно да се изберат за да се спречи оштетување на седлото и да се осигури оптимална позиција.

Посебно внимание мора да се посвети на состојбата на површината на оската, условите во куќиштето и параметрите на порамнетоста при монтажата. Овие фактори директно влијаат врз перформансите на седлото и можат значително да ја повлијаат службената трајност како на самото седло, така и на опремата која тоа ја штити.

Стратегии за превентивно одржување

Воведувањето на ефективни протоколи за одржување на синџири за ротирачки валови со висок притисок е суштинско за максимално проширување на нивниот век на траење и осигурување сигурна перформанса. Редовна проверка на состојбата на синџирот, набљудување на работните параметри и планирани интервали за замена помагаат да се спречат неочекувани кварови и скапи прекини во работата.

Програмите за одржување треба да вклучуваат редовна проценка на трошењето на синџирот, состојбата на подмазувањето и факторите од работната средина кои можат да влијаат на перформансите на синџирот. Проактивните стратегии за одржување помогнуваат да се утврдат потенцијални проблеми пред тие да доведат до квар на опремата.

Идни трендови и иновации

Паметни решенија за запечатување

Иднината на синџирите за ротирачки валови со висок притисок се формира со напредокот во паметните технологии и интеграцијата на сензори. Новите конструкции вклучуваат можност за набљудување која може да обезбеди вистинско временска повратна информација за перформансите на синџирот, состојбата на трошење и работните услови. Оваа интелигенција овозможува стратегии за предвидлив надзор и подобрување на сигурноста на опремата.

Интеграцијата на IoT сензори и системи за надзор со амбалажни склопови претставува значајна напредок во технологијата за одржување, овозможувајќи операторите да ја оптимизираат постапката за одржување и да спречат неочекувани кvarови.

Пристапи на одржлив дизајн

Еколошките разгледувања го поттикнуваат иновирањето во дизајнот на амбалажи и изборот на материјали. Се развиваат нови еко-пријателски материјали и производни процеси за да се намали влијанието врз животната средина, при што се одржува или подобрува перформансата на амбалажите. Овие напредоци вклучуваат биоразградливи материјали, конструкции со намалено триење и поефикасни производни процеси.

Одржливите пристапи исто така се насочени кон проширување на трајноста на амбалажите и намалување на отпадот преку подобрена издржливост и рециклабилни материјали, соодветно на глобалните иницијативи за еколошка одговорност во индустријските операции.

Често поставувани прашања

Кои фактори ја одредуваат трајноста на амбалажите за ротирачки валови со висок притисок?

Векот на траење на седлата за ротација под висок притисок зависи од повеќе фактори, вклучувајќи го работниот притисок, брзината, температурата, компатибилноста со подмазочувачот, квалитетот на монтажата и околинските услови. Правилниот избор на материјал и практиките за одржување исто така имаат клучна улога во одредувањето на траењето на седлата.

Колку често треба да се заменуваат седлата за ротација под висок притисок?

Интервалите за замена зависат од специфичните фактори за апликацијата и работните услови. Додека некои седла можат да траат неколку години при умерени услови, други во потешки услови можеби ќе бараат почеста замена. Редовното следење и проценките за одржување помагаат да се одреди оптималниот распоред за замена.

Што се знаците на неуспешни ротациони седла?

Чести индикатори на неуспех на седлата вклучуваат видливи цурења, зголемени работни температури, необичен шум или вибрации и намалена перформанса на опремата. Раното откривање на овие знаци преку редовна проверка помага да се спречат катастрофални неуспеси и да се минимизира штетата на опремата.