In hydraulic and pneumatic equipment, sealing elements are often overlooked until problems arise. One of the most widely used profiles is the U-cup seal, a design that has earned its place in countless cylinders, presses, and industrial machines. Understanding how these seals function, and how they differ from other options, can make a direct difference in equipment uptime and service costs.

Why the U-Shape Matters

The defining feature of a U-cup seal is its cross-section. The lips form a narrow gap that reacts to internal pressure. As the pressure increases, the lips expand and press more firmly against the mating surface. This self-energizing effect provides two key benefits:

Tight sealing at varying pressures – even when conditions fluctuate, the contact remains effective.

Durability in reciprocating motion – unlike O-rings, which tend to roll or twist under sliding motion, U-cups hold their position and resist extrusion.

Because of this geometry, U-cup seals are a natural choice for rod and piston sealing in hydraulic cylinders, where strokes are frequent and loads are heavy.

Material Choices and Their Impact

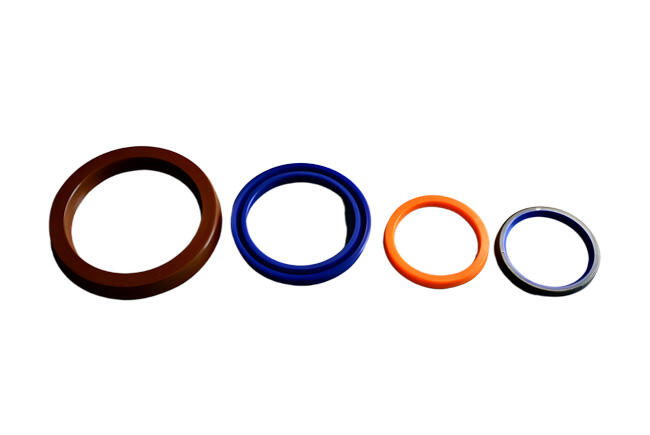

Selecting the right material is often more critical than choosing the seal profile itself. Some commonly used compounds include:

Polyurethane (PU): known for toughness and abrasion resistance, widely used in mobile hydraulics.

Fluorocarbon rubber (FKM): stable at higher temperatures and resistant to aggressive fluids.

The decision depends on the working medium, temperature range, and cycle frequency. A hydraulic press running hot fluids requires a different seal than a pneumatic cylinder in a packaging line.

Where U-Cup Seals Are Applied

Across industries, U-cup seals are found wherever controlled motion and high pressure intersect. Typical examples include:

Construction machinery such as excavators and cranes, where hydraulic cylinders face shock loads.

Industrial presses and forming machines, where cycle counts are high and downtime is costly.

Agricultural equipment, exposed to dust, mud, and variable operating speeds.

Automation systems and robotics, where compact actuators require precise sealing performance.

These applications illustrate that the role of a seal goes beyond preventing leaks—it is central to maintaining pressure stability and motion control.

Common Challenges in Practice

Despite their proven design, U-cup seals are not immune to problems. Field technicians often report:

Lip wear caused by contamination when dust or metal particles enter the system.

Hardening of rubber materials after prolonged exposure to elevated oil temperatures.

Extrusion damage in cases of high pressure without adequate back-up rings.

Preventive maintenance—such as monitoring oil cleanliness and inspecting cylinder surfaces—plays a crucial role in extending service life.

Practical Tips for Selection and Maintenance

Always match the material to the fluid type and temperature range.

Check the groove dimensions carefully; incorrect tolerances can shorten seal life.

In high-pressure systems, consider using anti-extrusion rings together with the U-cup.

For machines operating outdoors, select materials resistant to ozone and weathering.

U-cup seals may look simple, but their influence on system performance is significant. Their self-energizing lip design, combined with the right material choice, allows them to operate reliably in environments where O-rings or flat seals would fail.

Hot News

Hot News